Weightless metal X-ray

Space-age metals are already all around us and probably even in your pocket. Many smartphones use metals-alloys that were researched and perfected in space during the Space Shuttle era.

Many of the metals we use in our daily life are not pure, but an alloy of metals that combine the best of both materials. Creating new metals and even new molecular structures promises great advantages, but getting a stable uniform metal mix is not straightforward.

On Earth scientists investigating metals are hampered on atoms being influenced by gravity individually, adding an extra complication to the equation. This is where weightlessness steps in.

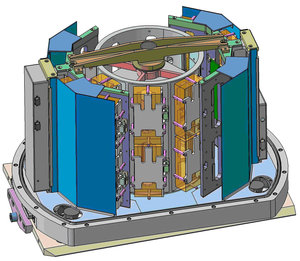

Investigating metals as they melt and solidify in weightlessness simplifies the equation and makes it easier to understand the underlying processes. ESA can offer an inside view with its XRMON facility that takes X-ray video of molten metals being cast in weightlessness.

The wonderful world of metals

Nothing less than a miniature furnace, XRMON can heat metals up to 1100°C and cast them by cooling them down quickly.

Researchers can observe dendrites – pine-tree-like impurities – that occur when metals cool. Understanding how these form is allowing industry deliver stronger metals from the production line that are being used in aircraft turbines to save weight and fuel.

Metal foams are another interesting application. Creating metals riddled with air bubbles offers rigidity but without the weight of a solid object. These metals are already being used in consumer cars for safety and fuel economy based on weightless research.

Adding small grains to a metal alloy like raisins to a cake mix, can help the atoms bond and improve the final product. Investigating this technique on sounding rockets shows potential to mass-produce novel alloys that offer the best the individual metals can offer, combined.