Advanced Manufacturing

Through the new Advanced Manufacturing initiative ESA aims to home in on emerging manufacturing technologies which open up new industrial possibilities in terms of design freedom, streamlined production stages and reduced cost, along with enhanced performance from the final product.

The opportunity is there to change the industry works, revising and rebuilding industrial supply chains, and, in the process, regaining lost manufacturing capabilities. Accordingly, the initiative is attracting strong interest from European industry.

The new possibilities opened up by computer-based concurrent engineering is an important part of the initiative, enabling teamwork focused on a common design model that evolves iteratively in real time as the different subsystem experts make their contributions. Computer-aided design techniques are also being optimised to take advantage of innovations in the subsequent production stages.

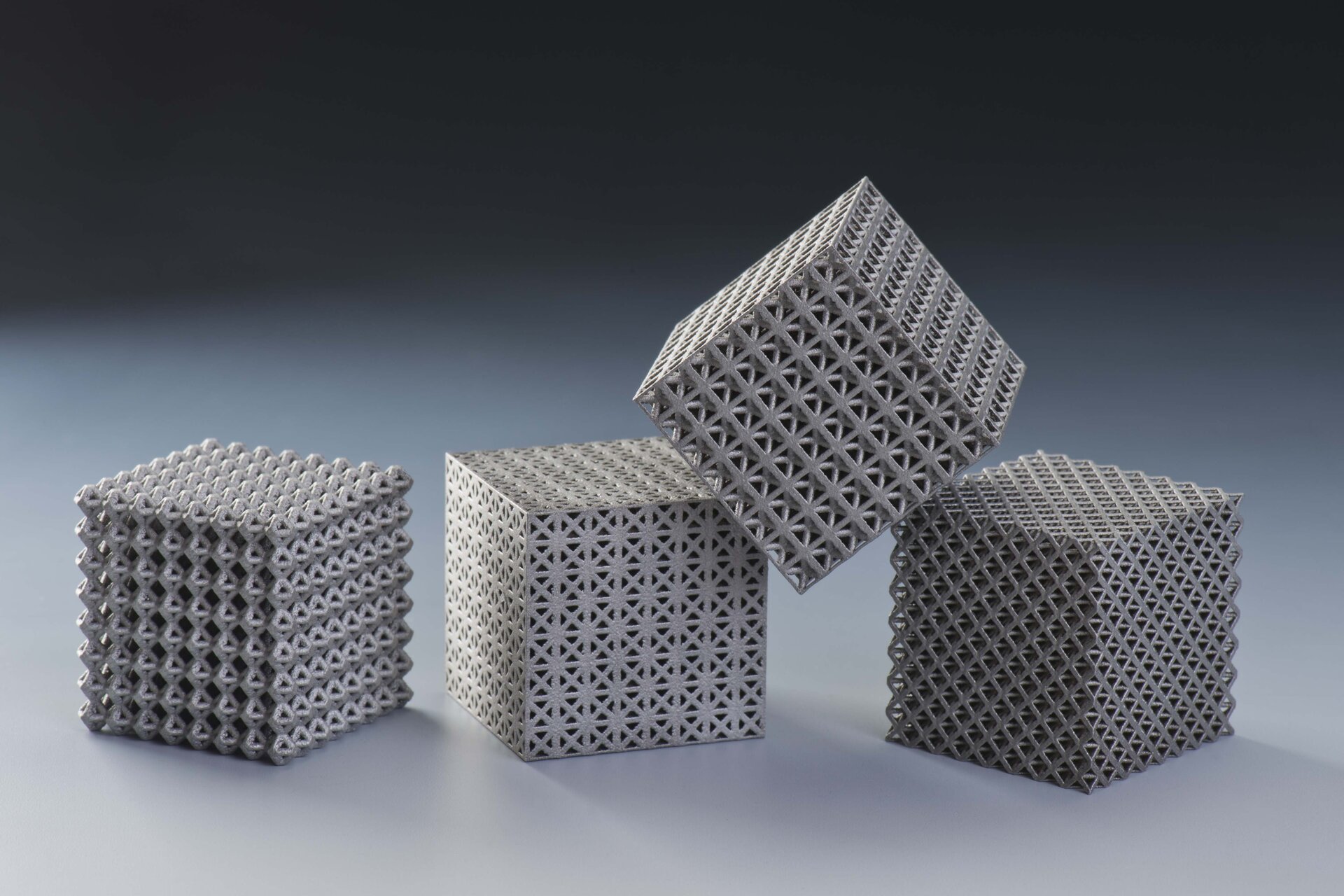

These include additive manufacturing, otherwise known as 3D printing, which builds up hardware layer by layer, enabling the construction of hardware that simply could not be built in any other manner. Extremely complicated shapes can be manufactured without the need for joins or welds, using less raw material and energy than traditional manufacturing, and with a reduced number of steps. This is in addition to other alternative production methods such as ‘friction stir welding’ for joining material.

The initiative will foster multi-sectorial cross-fertilisation, facilitating spin-in and spin-off opportunities across different high-end technology and industrial domains and infrastructure, opening new fields of innovation. It will promote the creation and dissemination of design as well as verification, qualification and standardisation methodologies.

The cross-cutting approach is introduced to foster a system level view of the introduction of these new technologies, with a coherent qualification approach across ESA programmes and non-ESA funded space activities. Initially three branches of the initiative have been identified, firstly ‘Basic Research and Preparatory Activities’ across the low TRLs, secondly ‘Main Technology Activities’ to build up sustainable supply chains in the higher TRLs and finally ‘Qualification, Verification and Standards’ aimed at facilitating the adoption of these advanced manufacturing technologies and processes by developing the necessary standards, verification and qualification. These activities will accelerate adoption by establishing a commonly-agreed pathway to flight acceptance.

Additive manufacturing (AM) has led the way, with the first steps in a harmonised approach involving ESA’s (THAG) has been taken with a mapping meeting and follow-up workshop in 2014. Around 700 experts have been involved, representing 26 countries and 390 companies. Some 62 new companies, predominantly small-to-medium enterprises joined the industry body Eurospace in order to participate.

The resulting roadmap is being finalised for publication, covering around 30 types of AM parts that would strongly benefit from being manufactured using AM and the entire end-to-end AM process, from initial modelling and design of items to material supply and processing and post-processing stages to qualification and standardisation. This latter element is all important for space. To give mission managers sufficient confidence in 3D-printed parts, methods need to be in place to ensure that these items perform to a benchmarked, repeatable standard. The eventual aim is to put a dedicated European Coordination on Space Standardization (ECSS) standard in place, for common use by all European space projects.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland