New lab for advanced manufacturing techniques and materials

ESA’s latest technical laboratory, inaugurated today by Director General Jan Woerner, will help to understand the capabilities of 3D printing and other advanced manufacturing techniques for future space missions.

The Advanced Manufacturing Laboratory is at the Science and Technology Facilities Council’s Rutherford Appleton Laboratory (RAL) in Harwell, Oxfordshire, directly adjacent to ESA’s UK facility.

A key aim of the laboratory is to exploit the expertise and world-leading facilities that are available on the Harwell Campus, to assess new material processes, joining techniques and 3D printing technologies for application in space.

“There’s a multitude of emerging technologies with apparent potential for producing stronger, lighter and cheaper spacecraft structures, but we have to be sure they are fully suitable for space with no show-stoppers,” explains Andrew Barnes, overseeing the new laboratory.

“Our laboratory aims to assess candidate materials and manufacturing processes for space missions, pre-screening them early in their development cycle.

“The results obtained will help guide ESA and the wider space industry in deciding where to focus future technology investments.”

The lab has access to a metal-based 3D printer and is equipped with a suite of powerful microscopes, an X-ray CT machine and a range of furnaces. Mechanical testing such as tensile and micro-hardness testing is also performed.

“We can also employ the many facilities available on the Harwell campus,” explains laboratory research fellow Sarah Baker. “These include access to semiconductor cleanrooms, cryogenic laboratories, the UK’s Central Laser Facility, the ISIS neutron source and the Diamond Light Source.”

“We’ve already been using STFC’s ISIS pulsed spallation neutron source to investigate the structural integrity of friction stir welded titanium for use in spacecraft propellant tanks.

“ISIS allows residual stress measurements to be performed in the bulk material using neutron diffraction.

“Friction welding involves a high speed rubbing together of metal parts rather than the application of external heat to melt the parts. The technique should result in stronger welds. ISIS has allowed us to confirm this by measuring the internal stresses induced by the process to confirm the final weld quality.”

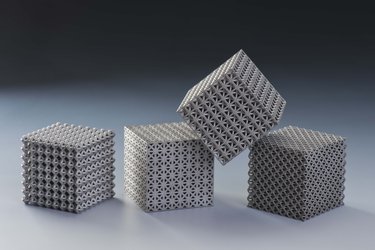

3D printing is a key focus of the laboratory, involving parts being built up layer by layer rather than being machined away from bulk material. The print material is typically a powder or wire feedstock that is melted using a laser or electron beam source.

Harwell will be looking at aspects such as the physical process parameters, the impact of powder feedstock and the design procedures used in order to assess the effect of 3D printing techniques upon the quality of manufactured parts.

The ESA–RAL Advanced Manufacturing Laboratory is the latest addition to a network of ESA laboratories across Europe, making their expertise available to ESA missions as well as to the wider space sector.

“The aim is to complement the work of ESA’s long-established Materials and Electrical Components Laboratory at ESA’s ESTEC technical centre in the Netherlands,” adds Tommaso Ghidini, head of the ESTEC materials technology section.

“At ESTEC, much of the work is on a rapid-response basis to support the needs of space projects, performing tests and failure analysis on materials and equipment, albeit at a relatively high technology readiness level.

“The Harwell facility complements ESTEC by focusing on low technology readiness level investigations. Here, we’re operating on a different basis, looking at samples right down to the nanometre scale to understand their underlying structure, and how it relates to their physical properties, so we can really deliver an inside-out understanding of a candidate material or process and catch early technologies with high potential for space applications.”

Chris Bee, the Head of Business Development at the UK’s Science and Technology Facilities Council, said, “This is exactly the sort of collaboration that brings the whole Harwell Campus community together at its best. The laboratory is already driving projects in exciting new areas and though our focus is on components for space, we hope that the laboratory’s impact on the campus can extend well beyond.

“We hope that this will encourage innovation with the UK’s high-tech industry sectors, bringing us additional advanced engineering challenges to solve using our cutting-edge national facilities.”

In particular, the lab will be supporting ESA’s new Advanced Manufacturing cross-cutting initiative, aiming to help the space sector adopt 3D printing, friction stir welding and novel composite materials and production techniques.