Small French firm behind Herschel’s giant mirror

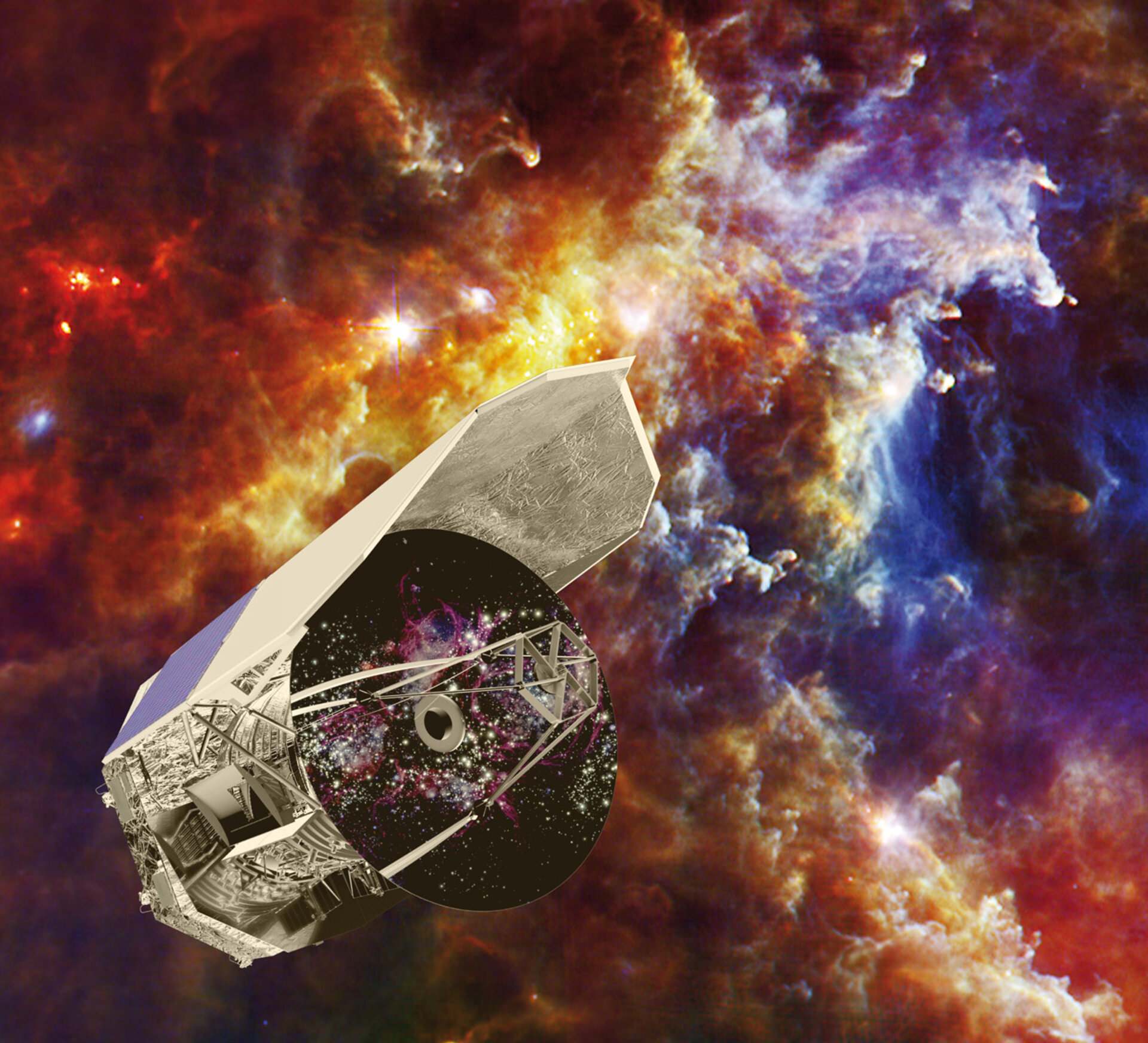

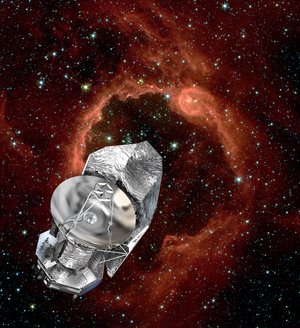

ESA’s Herschel telescope is surveying the infrared cosmos with the largest mirror flown in space. This 3.5 m-diameter reflector came from a small French firm whose workers once produced much more compact items: ceramic bearings and seals for industrial pumps.

What is really remarkable about Herschel’s mirror is less its large size than its low mass: at just a third the mass of the Hubble Space Telescope’s main mirror, it provides twice the observing area. It comes down to a very specific European technology mastered by a single company, working alongside ESA and Herschel prime contractor EADS Astrium.

“The case of silicon carbide manufacturer Boostec is a concrete example of how ESA works to maintain and expand Europe’s technology base, boosting the global competitiveness of European industry,” said Alberto Tobias, head of ESA’s Technology and Software Systems Department.

Based in Bazet near Toulouse, Boostec specialises in space optics. The 35-strong firm has made mirrors and optical supports for Herschel and other landmark missions, including Rosetta, Sentinel-2 and Gaia – ESA’s 3D Universe mapper.

“We were manufacturing for terrestrial industrial applications,” said Michel Bougoin, Optics Business Manager for Boostec. “What was then Matra Marconi Space – today Astrium – contacted us to say our silicon carbide held promise for space optics, and ask if we would work with them.”

Hard stuff from the stars

A compound of silicon and carbon – its chemical formula ‘SiC’ – silicon carbide was first synthesised in 1893 in an attempt to make artificial diamonds. The result was not so far off: today SiC is one of the hardest-known materials, used to make cutting tools, high-performance brakes and even bulletproof vests. Crystalline in nature, it is also used for jewellery.

Small amounts of SiC have been unearthed inside meteorites: it is relatively common in deep space. Its strong, lightweight nature made it a natural for man-made space projects too.

“Silicon carbide has two attractive properties for space,” explained Mr Bougoin. “It has very high ‘specific stiffness’ – its ratio of stiffness to weight – so SiC mirrors can be built to a very low mass but still maintain a precise structure.

“It is also relatively insensitive to temperature change, with a low ‘coefficient of thermal expansion’ coupled with high thermal conductivity. Anything in orbit experiences a wide range of temperatures, but SiC optics can endure these shifts without deformation.”

Harnessing SiC for space

In the 1980s the US began work on using SiC for space optics. Some mirrors were produced, including for NASA’s EO-1 mission. Such investigations focused on SiC composites, with molten silicon added to a carbon matrix. But they failed to master the material, ending up with a mixture of pure SiC with uncombined silicon and carbon, and were abandoned.

Around the same time, ESA was designing its next big infrared astronomy mission, and coming to grips with a technological challenge. What could the giant mirror of what became Herschel be made from? Glass was simply too heavy; other possibilities included aluminium and carbon fibre.

Mission planners were aware of the American SiC problems, but discovered that one small French company was manufacturing nearly pure silicon carbide material. This represented a whole new approach with a greater chance of success.

Recipe for success

The recipe used to make SiC depends on the properties required, explained Mr Bougoin: “We produce ‘sintered’ silicon carbide – very homogenous with low porosity and high mechanical strength.”

SiC powder is squeezed together into solid blocks of about a tonne. These relatively-soft blanks can be easily shaped into highly complex parts using computer-guided milling machines. Leftover SiC dust is recycled to make fresh blanks.

The next step is sintering: the parts are placed into a 2000°C furnace to be baked into ceramics. The pieces end up extremely hard – further machining needs diamond-headed grinding. Different parts can be brazed together using a silicon-based weld.

Scaling up for Herschel

For Herschel, the challenge was one of scale, explained Mr Bougoin: “We typically made 10 cm SiC parts; here we had to work at a scale of metres. It was not possible to make the mirror in a single piece. Instead it needed to be cut into 12 segments, then brazed together with techniques developed by French nuclear agency CEA.”

Unsure of the technique’s feasibility, in 1999 ESA’s Science Directorate supported construction of a smaller 1.35-m mirror prototype. Once complete, it briefly became the largest SiC structure ever constructed, a record soon taken by Herschel’s full-size mirror.

Its 3.5-m segments had to be shaped to optical precision with gaps between them of 15 microns (thousandths of a millimetre) or less, filled by molten silicon through capillary action.

When passed to Finnish firm Opteon for polishing, the mirror had a shape accuracy of 0.17 mm and an overall thickness of 3.5 mm. It weighed just 300 kg – a comparable glass reflector would weigh nearer 1.5 tonnes.

Herschel was finally launched on 14 May 2009, returning unprecedented images of some of the coolest objects in space.

From Herschel to Gaia

By then, SiC had been shown to be too good a solution not to share. Ahead of Herschel’s launch, Boostec finished SiC telescopes for ESA’s comet-intercepting Rosetta, Taiwan’s Formosat-2 and South Korea's COMS-1.

Since then, the company has made telescopes for Sentinel-2, Aeolus, EarthCARE and the Near-Infrared Spectrograph for the James Webb Space Telescope, and SiC parts for the magnetosphere-mapping Swarm constellation.

The technology is also being considered for Geo-Oculus, a mission under study to perform high-resolution observations from geostationary orbit.

Boostec’s single biggest technology challenge, however, has been the construction of Gaia, ESA’s spacecraft to create a 3D map of the billion stars making up our galactic neighbourhood.

Advances in milling software mean larger, more complex shapes are possible, says Mr Bougoin: “Gaia includes around a hundred SiC parts plus separate substrates to support a total of 106 CCD sensors. They are supported by a highly stiff ring called the torus.

“While Herschel was formed from 12 similar parts, this torus involved 19 individually shaped elements, which all had to be brazed at the same time, with only one chance to get it right.”

Achieved in July 2009, this milestone in Gaia development demonstrates the maturity of silicon carbide optics, the welcome outcome of a long-term technical partnership between ESA, Astrium and Boostec.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland