Accept all cookies Accept only essential cookies See our Cookie Notice

About ESA

The European Space Agency (ESA) is Europe’s gateway to space. Its mission is to shape the development of Europe’s space capability and ensure that investment in space continues to deliver benefits to the citizens of Europe and the world.

Highlights

ESA - United space in Europe

This is ESA ESA facts Member States & Cooperating States Funding Director General Top management For Member State Delegations European vision European Space Policy ESA & EU Space Councils Responsibility & Sustainability Annual Report Calendar of meetings Corporate newsEstablishments & sites

ESA Headquarters ESA ESTEC ESA ESOC ESA ESRIN ESA EAC ESA ESAC Europe's Spaceport ESA ESEC ESA ECSAT Brussels Office Washington OfficeWorking with ESA

Business with ESA ESA Commercialisation Gateway Law at ESA Careers Cyber resilience at ESA IT at ESA Newsroom Partnerships Merchandising Licence Education Open Space Innovation Platform Integrity and Reporting Administrative Tribunal Health and SafetyMore about ESA

History ESA Historical Archives Exhibitions Publications Art & Culture ESA Merchandise Kids Diversity ESA Brand Centre ESA ChampionsLatest

Space in Member States

Find out more about space activities in our 23 Member States, and understand how ESA works together with their national agencies, institutions and organisations.

Science & Exploration

Exploring our Solar System and unlocking the secrets of the Universe

Go to topicAstronauts

Missions

Juice Euclid Webb Solar Orbiter BepiColombo Gaia ExoMars Cheops Exoplanet missions More missionsActivities

International Space Station Orion service module Gateway Concordia Caves & Pangaea BenefitsLatest

Space Safety

Protecting life and infrastructure on Earth and in orbit

Go to topicAsteroids

Asteroids and Planetary Defence Asteroid danger explained Flyeye telescope: asteroid detection Hera mission: asteroid deflection Near-Earth Object Coordination CentreSpace junk

About space debris Space debris by the numbers Space Environment Report In space refuelling, refurbishing and removingSafety from space

Clean Space ecodesign Zero Debris Technologies Space for Earth Supporting Sustainable DevelopmentLatest

Applications

Using space to benefit citizens and meet future challenges on Earth

Go to topicObserving the Earth

Observing the Earth Future EO Copernicus Meteorology Space for our climate Satellite missionsCommercialisation

ESA Commercialisation Gateway Open Space Innovation Platform Business Incubation ESA Space SolutionsLatest

Enabling & Support

Making space accessible and developing the technologies for the future

Go to topicBuilding missions

Space Engineering and Technology Test centre Laboratories Concurrent Design Facility Preparing for the future Shaping the Future Discovery and Preparation Advanced Concepts TeamSpace transportation

Space Transportation Ariane Vega Space Rider Future space transportation Boost! Europe's Spaceport Launches from Europe's Spaceport from 2012Latest

3D printed Rudolf

Thank you for liking

You have already liked this page, you can only like it once!

This Rudolf the red-nosed reindeer was made using a patented 3D-printing process developed for producing strong and heat-resistant metal and ceramic lattices. Designed using a computer and printed in one go, in less than half an hour, this lightweight comes in at just over 12 grams.

Rudolf’s copper nose was produced using a new additive manufacturing technique. This patent is being developed further for use in space. A 3D metal printer is being developed to generate aluminium, copper and titanium alloy components in microgravity, eventually flying on the International Space Station.

3D printing, formally known as additive manufacturing, can create complex shapes that are impossible to manufacture with traditional casting and machining techniques. Little to no material is wasted and cutting the number of steps in a manufacturing chain offers enormous cost benefits.

This Rudolf is a festive example and test case of 3D printing. The next step is creating ceramic shapes that can withstand extreme temperatures. ESA and its partners have already built ceramic-lattice models which will be revealed in the new year.

ESA is testing these ceramic lattices for satellite thrusters. Coated in platinum, the ceramic acts as a catalyst to burn monopropellant – adding to safety, reliability and improving performance. Other applications being explored include using the technology for heat exchangers, catalytic convertors in cars and heat insulation.

The patents to make Rudolf come from ESA’s New Materials and Energy Unit in collaboration with Nick Adkins, Luke Carter and Hany Hassanin from Birmingham University, UK, and Wayne Voice and David Jarvis at ESA.

The project is part of ELIPS – European Programme for LIfe and Physical Sciences in Space, ESA’s research programme for science and applications in microgravity, helping to improve our life on Earth and enable humankind’s long-term presence in space.

Part of this research was carried out in the AMAZE project – Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products – and partially funded by the European Commission’s Seventh Framework Programme under contract FoF.NMP.2012-4.313781.

-

CREDIT

ESA -

LICENCE

ESA Standard Licence

Move over plastic: desktop 3D printing in metal or ceramics

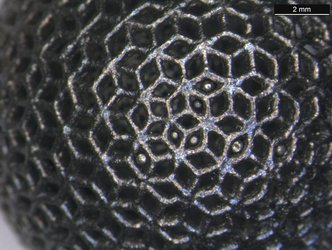

Close-up of 3D-printed titanium lattice ball

3D-printed ceramic parts made from lunar regolith

Parts 3D printed in aluminia

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland