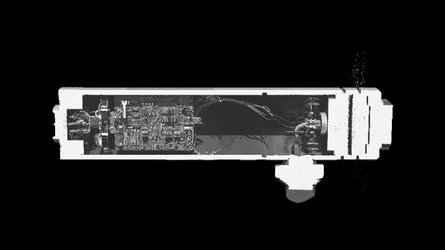

X-ray tomography machine

The engineers of ESA’s Materials and Electrical Components Laboratory – tasked with studying candidate parts for space missions – have an armoury of specialist equipment to turn to, including one very heavy piece of kit.

This giant X-ray tomography machine weighs in at 7.5 tonnes, including its internal lead screens. When it was installed, its sheer weight sunk the floor of the Lab by about 4.5 mm.

The machine is the engineering equivalent of a medical CT scanner – and does an equivalent job, revealing the details of the interior of a test item without destroying it in the process.

The test part is slowly moved around as a thousand X-ray images are taken. Then specialised software stacks these individual images into a detailed 3D model.

Total acquisition time depends on the size of the part – it might be completed in six to seven hours. For a larger part multiple acquisitions might need to be performed across different sections of the part, then merged.

The resulting 3D model has a spatial resolution down to around 0.03 mm, portraying not only its surface but also its interior features, so that the engineers can perform a detailed flythrough around – and deep inside – the test part.

ESA’s Materials and Electrical Components Laboratory is one of a portfolio of labs at the Agency’s ESTEC technical centre in Noordwijk, the Netherlands.