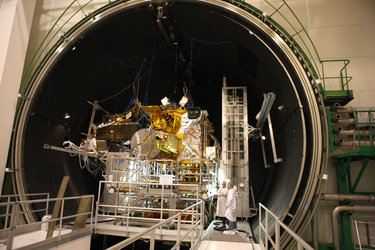

Silicon carbide mirror subjected to thermal–vacuum testing

A strong but lightweight mirror for space, made from silicon carbide ceramic, is being subjected to the temperature levels and vacuum encountered in orbit.

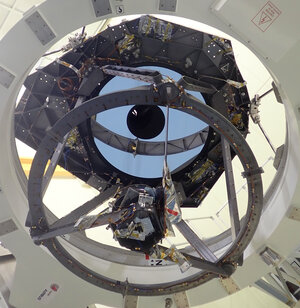

The 95 cm-diameter mirror consists of three separate petals fused together ahead of grinding and polishing.

The aim of the test, led for ESA by AMOS in Belgium, was to check if the combination of joints would induce optical distortion when the mirror’s temperature was brought close to –150°C.

A compound of silicon and carbon, SiC was first synthesised in 1893 in an attempt to make artificial diamonds. The result was not so far off: today, SiC is one of the hardest-known materials, used to make cutting tools, high-performance brakes and even bulletproof vests. Crystalline in nature, it is also used for jewellery.

Small amounts of SiC have been unearthed inside meteorites – it is relatively common in deep space. Its strong, lightweight nature made it a natural for human-made space projects too.

ESA produced the largest SiC mirror ever to fly in space for the Herschel telescope, launched in 2009. At 3.5 m in diameter, this reflector had twice the observing area of the Hubble Space Telescope while having one third of its mass.

Once mastered by ESA, SiC technology has since been used to manufacture a wide variety of space mirrors and optical supports, for missions such as Gaia, Sentinel-2 and the James Webb Space Telescope.

Performed through ESA’s General Support Technology Programme, which develops promising technologies for space, the results of the test proved to be perfectly acceptable for optical telescopes. To find out more about ESA research and development projects, check our new Shaping the Future website.