Accept all cookies Accept only essential cookies See our Cookie Notice

About ESA

The European Space Agency (ESA) is Europe’s gateway to space. Its mission is to shape the development of Europe’s space capability and ensure that investment in space continues to deliver benefits to the citizens of Europe and the world.

Highlights

ESA - United space in Europe

This is ESA ESA facts Member States & Cooperating States Funding Director General Top management For Member State Delegations European vision European Space Policy ESA & EU Space Councils Responsibility & Sustainability Annual Report Calendar of meetings Corporate newsEstablishments & sites

ESA Headquarters ESA ESTEC ESA ESOC ESA ESRIN ESA EAC ESA ESAC Europe's Spaceport ESA ESEC ESA ECSAT Brussels Office Washington OfficeWorking with ESA

Business with ESA ESA Commercialisation Gateway Law at ESA Careers Cyber resilience at ESA IT at ESA Newsroom Partnerships Merchandising Licence Education Open Space Innovation Platform Integrity and Reporting Administrative Tribunal Health and SafetyMore about ESA

History ESA Historical Archives Exhibitions Publications Art & Culture ESA Merchandise Kids Diversity ESA Brand Centre ESA ChampionsLatest

Space in Member States

Find out more about space activities in our 23 Member States, and understand how ESA works together with their national agencies, institutions and organisations.

Science & Exploration

Exploring our Solar System and unlocking the secrets of the Universe

Go to topicAstronauts

Missions

Juice Euclid Webb Solar Orbiter BepiColombo Gaia ExoMars Cheops Exoplanet missions More missionsActivities

International Space Station Orion service module Gateway Concordia Caves & Pangaea BenefitsSpace Safety

Protecting life and infrastructure on Earth and in orbit

Go to topicAsteroids

Asteroids and Planetary Defence Asteroid danger explained Flyeye telescope: asteroid detection Hera mission: asteroid deflection Near-Earth Object Coordination CentreSpace junk

About space debris Space debris by the numbers Space Environment Report In space refuelling, refurbishing and removingSafety from space

Clean Space ecodesign Zero Debris Technologies Space for Earth Supporting Sustainable DevelopmentLatest

Applications

Using space to benefit citizens and meet future challenges on Earth

Go to topicObserving the Earth

Observing the Earth Future EO Copernicus Meteorology Space for our climate Satellite missionsCommercialisation

ESA Commercialisation Gateway Open Space Innovation Platform Business Incubation ESA Space SolutionsLatest

Enabling & Support

Making space accessible and developing the technologies for the future

Go to topicBuilding missions

Space Engineering and Technology Test centre Laboratories Concurrent Design Facility Preparing for the future Shaping the Future Discovery and Preparation Advanced Concepts TeamSpace transportation

Space Transportation Ariane Vega Space Rider Future space transportation Boost! Europe's Spaceport Launches from Europe's Spaceport from 2012Latest

Heat sterilisation of ExoMars parachute

Thank you for liking

You have already liked this page, you can only like it once!

A technician places a nearly 70 kg parachute designed for ESA and Roscosmos’s ExoMars 2020 mission inside the dry heater steriliser of the Agency’s Life, Physical Sciences and Life Support Laboratory, based in its Netherlands technical centre.

Mars is a potential abode of past and perhaps even present-day life. Accordingly, international planetary protection regulations require any mission sent to the Red Planet to undergo rigorous sterilisation, to prevent terrestrial microbes from piggybacking their way there.

The Lab’s Alan Dowson explains: “This is the ‘qualification model’ of the 35-m diameter main parachute for ExoMars 2020, basically a test version which allows us to finalise our sterilisation procedures ahead of the flight model chute’s arrival.

“This version has been threaded with thermal sensors, allowing us to see how long it takes to reach the required sterilisation temperature in all parts of the folded parachute, even in the hardest to heat points. Our target was to sterilise at 125 °C for 35 hours and 26 minutes, and the oven took about 44 hours to reach that temperature to begin with.”

The oven is part of the Lab’s 35 sq. m ‘ISO Class 1’ cleanroom, one of the cleanest places in Europe. All the cleanroom’s air passes through a two-stage filter system. Anyone entering the chamber has to gown up in a much more rigorous way than a hospital surgeon, before passing through an air shower to remove any remaining contaminants.

“If you imagine our clean room as being as big as the entire Earth’s atmosphere, then its allowable contamination would be equal to a single hot air balloon,” adds Alan. “Our ISO 1 rating means we have less than 10 dust particles measuring a tenth of one millionth of a metre in diameter per cubic metre of air.”

The mostly nylon and Kevlar parachute, packed into an 80-cm diameter donut-shaped unit, was delivered by Italy’s Arescosmo company. This qualification model will now be sent back there for testing, to ensure this sterilisation process causes no change to the parachute’s material properties.

Alan explains: “We will receive the parachute flight model later this spring for the same sterilisation process – identical to this version, except without any thermal sensors.”

ExoMars’s smaller first stage 15-m diameter parachute has already gone through sterilisation using the oven. This is the parachute that opens during initial, supersonic atmospheric entry, with the second, larger chute opening once the mission has been slowed to subsonic velocity.

The Lab has also tackled a variety of ExoMars instruments and subsystems, but this second stage subsonic parachute is the single largest item to be sterilised. The sterilisation process aims to reduce the overall mission ‘bioburden’ to a 10 thousandth of its original level.

-

CREDIT

ESA–M. Cowan -

LICENCE

ESA Standard Licence

Sterilisation for planetary protection

Sterilising an antenna for Mars

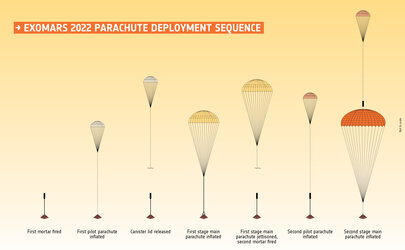

ExoMars 2022 parachute deployment sequence

ExoMars parachute high-altitude drop test

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland