Accept all cookies Accept only essential cookies See our Cookie Notice

About ESA

The European Space Agency (ESA) is Europe’s gateway to space. Its mission is to shape the development of Europe’s space capability and ensure that investment in space continues to deliver benefits to the citizens of Europe and the world.

Highlights

ESA - United space in Europe

This is ESA ESA facts Member States & Cooperating States Funding Director General Top management For Member State Delegations European vision European Space Policy ESA & EU Space Councils Responsibility & Sustainability Annual Report Calendar of meetings Corporate newsEstablishments & sites

ESA Headquarters ESA ESTEC ESA ESOC ESA ESRIN ESA EAC ESA ESAC Europe's Spaceport ESA ESEC ESA ECSAT Brussels Office Washington OfficeWorking with ESA

Business with ESA ESA Commercialisation Gateway Law at ESA Careers Cyber resilience at ESA IT at ESA Newsroom Partnerships Merchandising Licence Education Open Space Innovation Platform Integrity and Reporting Administrative Tribunal Health and SafetyMore about ESA

History ESA Historical Archives Exhibitions Publications Art & Culture ESA Merchandise Kids Diversity ESA Brand Centre ESA ChampionsLatest

Space in Member States

Find out more about space activities in our 23 Member States, and understand how ESA works together with their national agencies, institutions and organisations.

Science & Exploration

Exploring our Solar System and unlocking the secrets of the Universe

Go to topicAstronauts

Missions

Juice Euclid Webb Solar Orbiter BepiColombo Gaia ExoMars Cheops Exoplanet missions More missionsActivities

International Space Station Orion service module Gateway Concordia Caves & Pangaea BenefitsLatest

Space Safety

Protecting life and infrastructure on Earth and in orbit

Go to topicAsteroids

Asteroids and Planetary Defence Asteroid danger explained Flyeye telescope: asteroid detection Hera mission: asteroid deflection Near-Earth Object Coordination CentreSpace junk

About space debris Space debris by the numbers Space Environment Report In space refuelling, refurbishing and removingSafety from space

Clean Space ecodesign Zero Debris Technologies Space for Earth Supporting Sustainable DevelopmentLatest

Applications

Using space to benefit citizens and meet future challenges on Earth

Go to topicObserving the Earth

Observing the Earth Future EO Copernicus Meteorology Space for our climate Satellite missionsCommercialisation

ESA Commercialisation Gateway Open Space Innovation Platform Business Incubation ESA Space SolutionsLatest

Enabling & Support

Making space accessible and developing the technologies for the future

Go to topicBuilding missions

Space Engineering and Technology Test centre Laboratories Concurrent Design Facility Preparing for the future Shaping the Future Discovery and Preparation Advanced Concepts TeamSpace transportation

Space Transportation Ariane Vega Space Rider Future space transportation Boost! Europe's Spaceport Launches from Europe's Spaceport from 2012Latest

3D printing and milling Athena optic bench

Thank you for liking

You have already liked this page, you can only like it once!

Twin robotic arms work together as part of a project to construct what will be the largest, most complex object ever 3D printed in titanium: a test version of the 3-m diameter ‘optic bench’ at the heart of ESA’s Athena X-ray observatory.

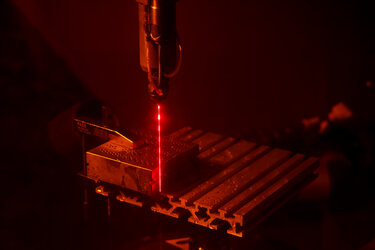

The first multi-axis robotic arm builds up each new layer of metal using a laser to melt titanium powder. The second robotic arm then immediately cuts away any imperfections using a cryogenically cooled milling tool. The bench itself is placed on a slowly moving 3.4-m diameter turntable.

“ESA has teamed up with Germany’s Fraunhofer Institute for Material and Beam Technology for this exploratory activity,” explains ESA materials and processes engineer Johannes Gumpinger. “The final design of Athena’s optic bench is still to be decided, but if it will be built in titanium then its size and complexity is such that it could not be built in any other way.”

Due to launch in 2031, ESA’s Athena mission will probe 10 to 100 times deeper into the cosmos than previous X-ray missions, to observe the very hottest, high-energy celestial objects.

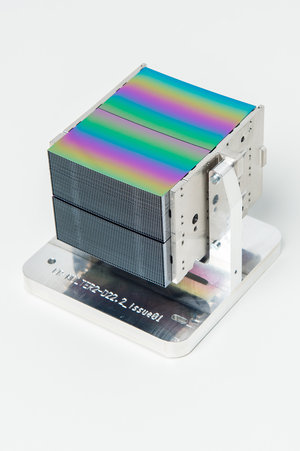

The mission requires entirely new X-ray optics technology, with stacks of ‘mirror modules’ arranged carefully to capture and focus high-energy X-rays.

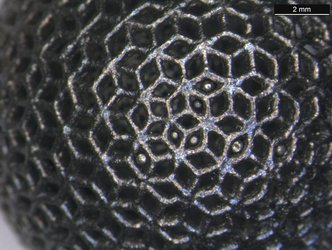

The optic bench aligns and secures around 750 mirror modules in a complex structure with many deep pockets that tapers out to a maximum height of 30 cm. Its overall shape needs to be precise down to a scale of a few tens of micrometres – or thousandths of a centimetre.

“The optic bench’s complexity requires each addition to be milled immediately after printing,” comments André Seidel, overseeing the project at the Fraunhofer Institute for Material and Beam Technology. “Any subsequent modification could risk introducing contamination, weakening the space-quality titanium.

“Similarly, the entire process has been designed to minimise any risk of contamination. The titanium powder is swept into the laser using the noble gas argon that also prevents any contamination with air. And the milling tool is kept cool using liquid carbon dioxide that evaporates as it warms up, preventing any harmful deposition on the freshly-laid metal surface.”

Precision sensors immediately detect any out of tolerance elements for milling or more extensive repair – including milling away for reprinting.

Smaller segments have been manufactured so far, with a 1.5-m diameter demonstrator optic bench set to follow. The full scale 3-m bench is expected to take about a year to produce.

“It will be a huge task, taking a lot of time and energy,” adds Johannes. “But if we manage it, it will be the largest titanium object ever 3D printed – and the process will be available to manufacture other large parts, potentially in other metals.”

The project is being supported through ESA’s Technology Development Element as part of the Agency’s Advanced Manufacturing initiative, harnessing novel materials and processes for the space sector.

Last month more than 150 experts from all across Europe met at ESA’s technical heart in the Netherlands to share the latest results from ESA Advanced Manufacturing projects covering topics including 3D printing and the latest composite materials as well as friction stir-welding.

How we make a space mission

ESA is Europe’s space agency, enabling its 22 Member States to achieve results that no individual nation can match. ESA combines space mission development with supporting labs, test and operational facilities plus in-house experts covering every aspect of space, supported through the Agency’s Basic Activities.

-

CREDIT

Fraunhofer IWS -

LICENCE

ESA Standard Licence

3D printing titanium for ESA’s Athena

Ins and outs of 3D printing

Athena mirror module

Laser light sabre

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland