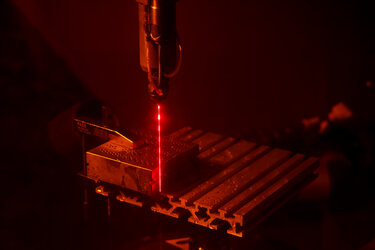

Ribs diced into silicon plate

Ribs diced into silicon wafers as part of the silicon pore optics production process, as seen through an electron microscope. The pores in between the ribs have a width of approximately 1 mm.

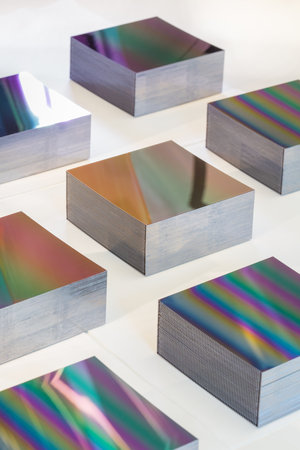

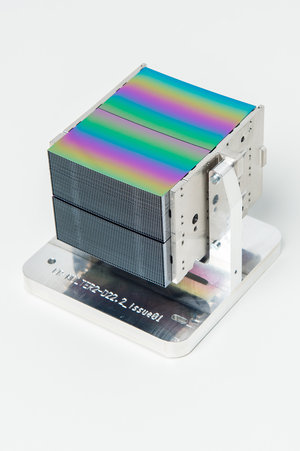

The process begins with industry standard 300 mm diameter silicon wafers, which are already polished to optical standards by their manufacturers. The wafers are cut into a set of squares measuring 66x66 mm each, which then have ribs diced into them. As plates are stacked together the gaps between the ribs created pores though which X-rays pass.

Silicon pore optics is being developed by ESA as part of the IXO candidate mission, as a means of producing stiff but lightweight X-ray mirrors. The aim is to produce a 20-fold increase in collecting area over the current XMM-Newton mission.