Aerosol Inkjet Printing

Thank you for liking

You have already liked this page, you can only like it once!

A TDE funded activity, performed by CSEM (Switzerland), successfully designed and manufactured the first ever tribology free (providing potentially infinite life) flexible mechanism element with built-in electrical signal transfer and sensing technology. Each flexible element contained custom printed strain gauge sensors and electrical transfer lines (including printed connectors) for positioning and potentially health monitoring. Additive Manufacturing (AM), three-dimensional (3D) printing techniques, were used throughout.

The flexible structures are representative of complaint mechanisms, such as, flexible pivots and tape springs for the deployment of solar panels and antenna booms. Two different breadboards were designed and tested raising the technology readiness level from two (application formulated) to four (functional verification). Aerosol Jet Printing was also shown to be a promising technique for integrating sensors, especially when combined with additive manufacturing.

-

CREDIT

ESA -

LICENCE

ESA Standard Licence

Drop Your Thesis! 2016 - Breakteam

Printed nerves for a satellite

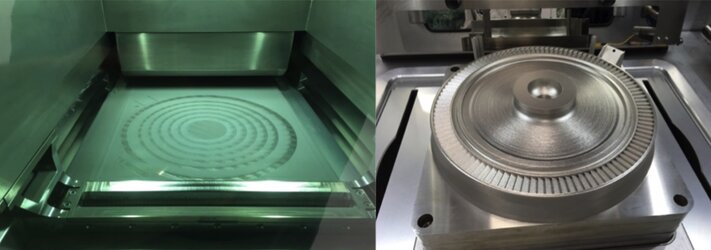

3D-printed turbo pump for Prometheus rocket engine

3D-printed lunar floor