Gift wrapped for Ariane 6

Thank you for liking

You have already liked this page, you can only like it once!

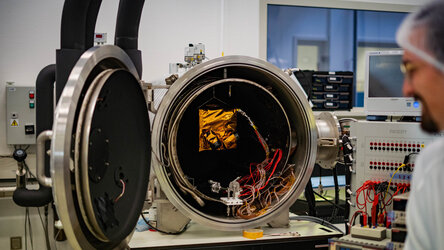

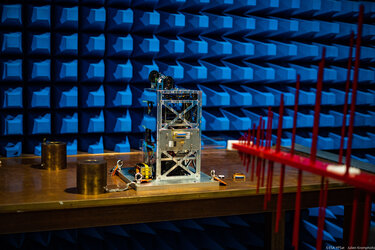

Wrapping presents is all part of the Christmas experience – here’s a notable example from ESA’s technical centre ESTEC. This is the ESA Young Professionals Satellite, YPSat, seen fully wrapped in multi-layer insulation blankets, exactly as it will be when it launches aboard the inaugural Ariane 6 mission next year.

YPSat is a project run in its entirety by ESA Young Professionals to give them direct early experience in designing, building and testing hardware for space. Equipped with cameras, a quantum-based magnetic sensor and an amateur radio unit, YPSat’s goal is to capture all the key phases of Ariane 6's first flight.

“Wrapping a payload in multi-layer insulation is as much of an art as a science,” comments Julien Krompholtz, YPSat’s current project manager. “The 10 layers of MLI enshrouding the payload represents an essential part of our thermal design, helping ensure that YPSat’s On-Board Computer in particular maintains an optimum operating temperature as it flies in orbit on Ariane 6.”

MLI blankets are made up of multiple layers of very thin, metal-coated plastic film, with low-conducting ‘spacer’ material placed in-between such as silk, nylon or glass-fibre netting. Alternatively, MLI is sometimes deliberately crinkled to minimise any contact between layers.

The reason they are so often wrapped around space hardware? In the vacuum of space, objects can be hot and cold at the same time, especially if one side is in sunshine and another is in shade. In such conditions, thermal radiation is the main driver of temperature change (rather than convection or conduction), and reflective MLI serves to minimise its impact.

In addition, YPSat also a incorporates a ‘Phase Change Material’ called Docosane. As the payload’s operation generates heat, this substance will melt, absorbing the unwanted thermal energy, like the evaporation of your sweat serving to cool you down.

-

CREDIT

ESA-J. Krompholtz -

LICENCE

ESA Standard Licence

YPSat’s trial by vacuum

All-in-one YPSat, Ariane 6 bound

It’s a wrap

YPSat checked in for Ariane 6 flight