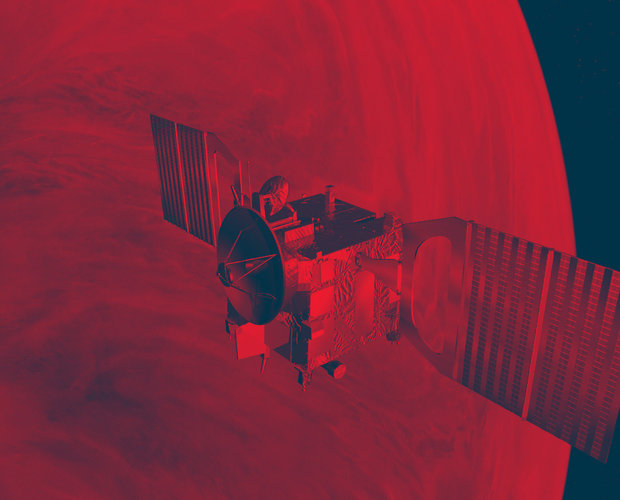

Venus Express propulsion and electrical system tests

Activities taking place in Baikonur, Kazakhstan, over the last two weeks have been focused on getting the ESA Venus Express spacecraft ready for the critical propellant loading activity, which is due to start on 24 September.

These first tests were a verification of the spacecraft's propulsion system and a basic electrical and functional check of the spacecraft.

Teams have been working extended hours on several occasions to stay on the planned schedule, and the tests were completed successfully and on time.

Back on 8 August, the spacecraft and all its ground support equipment were first unpacked after arrival and set up in the Hazardous Processing Facility. This is where the engineers ensured that the Venus Express propulsion system and pressurising mechanisms were functioning correctly.

The propulsion system tests started on 11 August and ran to 15 August. These included operation of all valves of the propulsion system, including the flow control valves of the 400-Newton thrust main engine, to be used for the Venus Orbit Insertion manoeuvre, and the smaller 10 Newton reaction control thrusters (RCTs) required to control the attitude of the spacecraft.

Then all branches of the propulsion system were pressurised, including the high-pressure helium tank and the two propellant tanks which will carry the fuel and the oxidiser, to check for leaks.

The spacecraft was then moved to the Payload Processing Facility on 16 August for electrical and functional testing, including on-ground simulation of actual mission scenarios.

This testing was carried out between 17-27 August. It involved the verification of the basic functioning of all spacecraft subsystems, such as:

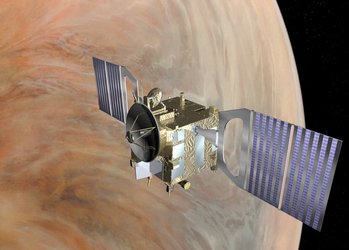

- the power subsystem, for example, checking it would provide all other on-board units with regulated electrical power from either the solar array wings or the three lithium-ion batteries;

- the Data Management System (DMS), the on-board computer system that is the ‘brain’ of the spacecraft which both distributes commands to and collects telemetry from all other on-board units;

- the Attitude and Orbit Control and Measurement System (AOCMS), including all sensors of the spacecraft’s attitude and motion, and actuators that control the attitude and pointing;

- the Telemetry, Tracking & Commanding subsystem which will relay all spacecraft telemetry to, and receive telecommands from, the Mission Operations Centre at ESOC.

The final flight version of the on-board software was uploaded to the spacecraft's central computer memory, to allow mission simulation testing to be carried out. This is where the spacecraft’s sensors are fed simulated data in terms of the attitude and solar illumination conditions (in a so-called ‘closed loop’ configuration) and the ‘reaction’ of the spacecraft to this perceived environment is monitored by the specialist teams.

The next planned activity is the ‘end-to-end’ verification of communications and operations – meaning that links will be tested from the Mission Operations Centre (MOC) at ESA's European Space Operations Centre (ESOC), in ESOC in Darmstadt, Germany, through to the spacecraft in Baikonur.

In this test, ESOC are actually taking command of the spacecraft and remotely operate and monitor it for a five-day period from 29 August to 2 September, so that the engineers can confirm that the ground stations and Venus Express can ‘talk’ properly to each other over the course of the mission.