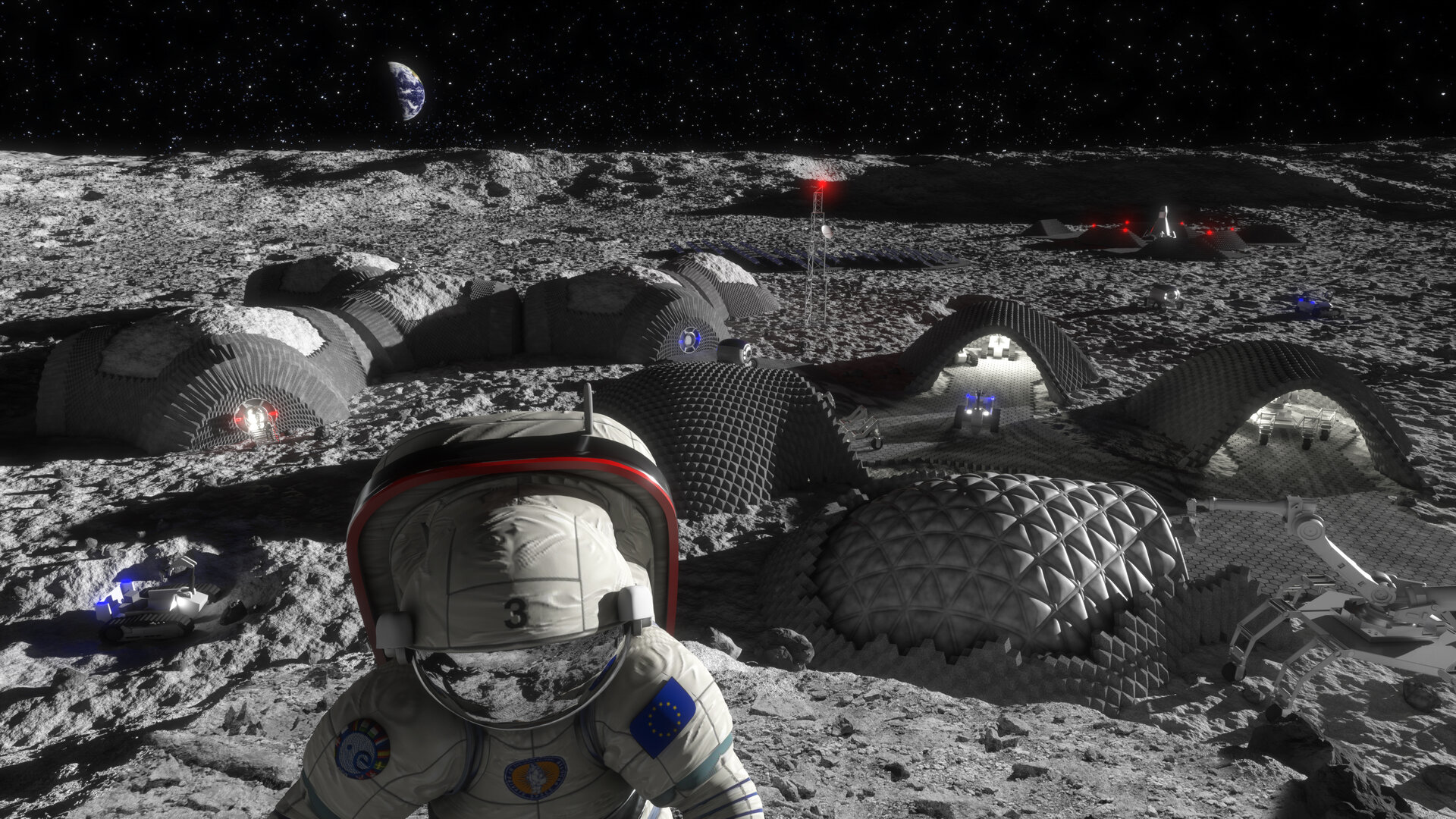

Future Moon base

Thank you for liking

You have already liked this page, you can only like it once!

A vision of a future Moon base that could be produced and maintained using 3D printing.

Habitat modules are seen beside ‘garages’ for rovers, with an adjacent launch site. Note the robotic vehicles on the surface, proceeding with base construction.

A new ESA-led project is investigating the ways that 3D printing could be used to create and run a habitat on the Moon, reducing logistical dependency on Earth. Everything from building materials to solar panels, equipment and tools to clothes, even nutrients and food ingredients can potentially be 3D printed – as detailed in this new video.

Space agencies around the world are considering the concept of a lunar base as a possible next step in human space exploration – and 3D printing represents a key technology for making it happen.

The aim would be to ‘live off the land’ as much as possible, by printing as many structures, items and spares out of lunar regolith as possible, or by using and reusing materials brought for the mission, rather than continuously relying on the long, expensive supply line from Earth.

Maximised 3D printing would also allow on-demand production of items and spares with routine recycling of materials available within the base, making lunar settlement much more self-sufficient and sustainable.

“The selected print processes would allow available materials to be recycled for different purposes,” explains Antonella Sgambati of OHB System AG, managing the project. “Another major benefit of 3D printing – otherwise known as additive manufacturing – is the breadth of design options it allows. Components, products and the print process itself can be redesigned based on their intended final usage in the lunar base. Decisions can be made on how best to link available materials with the hardware to be printed.”

Supported through ESA’s Basic Activities, this ‘Conceiving a Lunar Base Using 3D Printing Technologies’ project is being run by the URBAN consortium led by Germany’s OHB System AG, with extreme environments specialist Comex in France, Austrian design company Liquifer Systems Group and spacecraft structures manufacturer Sonaca Space in Germany.

-

CREDIT

RegoLight, visualisation: Liquifer Systems Group, 2018 -

LICENCE

ESA Standard Licence

Lunar base made with 3D printing

3D-printing a lunar base

Lunar building block at Hypervital

Infographic: 3D printing for a Moon base