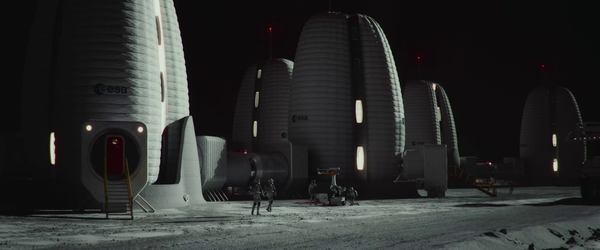

3D printing floor for lunar base study

A skeletal floor design for the ESA-supported lunar habitat design – created by leading architects Skidmore, Owings and Merrill and currently on show at this year’s Venice Biennale – was 3D printed in stainless steel by Dutch company MX3D, famous for creating a 3D-printed bridge in Amsterdam.

Designed to meet efficiency, use, and construction constraints, the structure’s smooth web pattern design emerged from delineating stress map analysis and optimising a continuous topology to reduce mass and make maximum use of 3D printing manufacturing methods.

It was printed using robotic ‘wire arc additive manufacturing’ out of 308LSi stainless steel and took about 246 hours to make, adding up to a total mass of approximately 395 kg .

This prototype was not able to be exhibited at SOM’s Biennale show, entitled ‘Life Beyond Earth’, but shows the scale of the four-storey semi-inflated habitat the company has devised for their design study of future lunar settlement.