Accept all cookies Accept only essential cookies See our Cookie Notice

About ESA

The European Space Agency (ESA) is Europe’s gateway to space. Its mission is to shape the development of Europe’s space capability and ensure that investment in space continues to deliver benefits to the citizens of Europe and the world.

Highlights

ESA - United space in Europe

This is ESA ESA facts Member States & Cooperating States Funding Director General Top management For Member State Delegations European vision European Space Policy ESA & EU Space Councils Responsibility & Sustainability Annual Report Calendar of meetings Corporate newsEstablishments & sites

ESA Headquarters ESA ESTEC ESA ESOC ESA ESRIN ESA EAC ESA ESAC Europe's Spaceport ESA ESEC ESA ECSAT Brussels Office Washington OfficeWorking with ESA

Business with ESA ESA Commercialisation Gateway Law at ESA Careers Cyber resilience at ESA IT at ESA Newsroom Partnerships Merchandising Licence Education Open Space Innovation Platform Integrity and Reporting Administrative Tribunal Health and SafetyMore about ESA

History ESA Historical Archives Exhibitions Publications Art & Culture ESA Merchandise Kids Diversity ESA Brand Centre ESA ChampionsLatest

Space in Member States

Find out more about space activities in our 23 Member States, and understand how ESA works together with their national agencies, institutions and organisations.

Science & Exploration

Exploring our Solar System and unlocking the secrets of the Universe

Go to topicAstronauts

Missions

Juice Euclid Webb Solar Orbiter BepiColombo Gaia ExoMars Cheops Exoplanet missions More missionsActivities

International Space Station Orion service module Gateway Concordia Caves & Pangaea BenefitsLatest

Space Safety

Protecting life and infrastructure on Earth and in orbit

Go to topicAsteroids

Asteroids and Planetary Defence Asteroid danger explained Flyeye telescope: asteroid detection Hera mission: asteroid deflection Near-Earth Object Coordination CentreSpace junk

About space debris Space debris by the numbers Space Environment Report In space refuelling, refurbishing and removingSafety from space

Clean Space ecodesign Zero Debris Technologies Space for Earth Supporting Sustainable DevelopmentLatest

Applications

Using space to benefit citizens and meet future challenges on Earth

Go to topicObserving the Earth

Observing the Earth Future EO Copernicus Meteorology Space for our climate Satellite missionsCommercialisation

ESA Commercialisation Gateway Open Space Innovation Platform Business Incubation ESA Space SolutionsLatest

Enabling & Support

Making space accessible and developing the technologies for the future

Go to topicBuilding missions

Space Engineering and Technology Test centre Laboratories Concurrent Design Facility Preparing for the future Shaping the Future Discovery and Preparation Advanced Concepts TeamSpace transportation

Space Transportation Ariane Vega Space Rider Future space transportation Boost! Europe's Spaceport Launches from Europe's Spaceport from 2012Latest

Hall of mirrors for Proba-3 laser testing

Thank you for liking

You have already liked this page, you can only like it once!

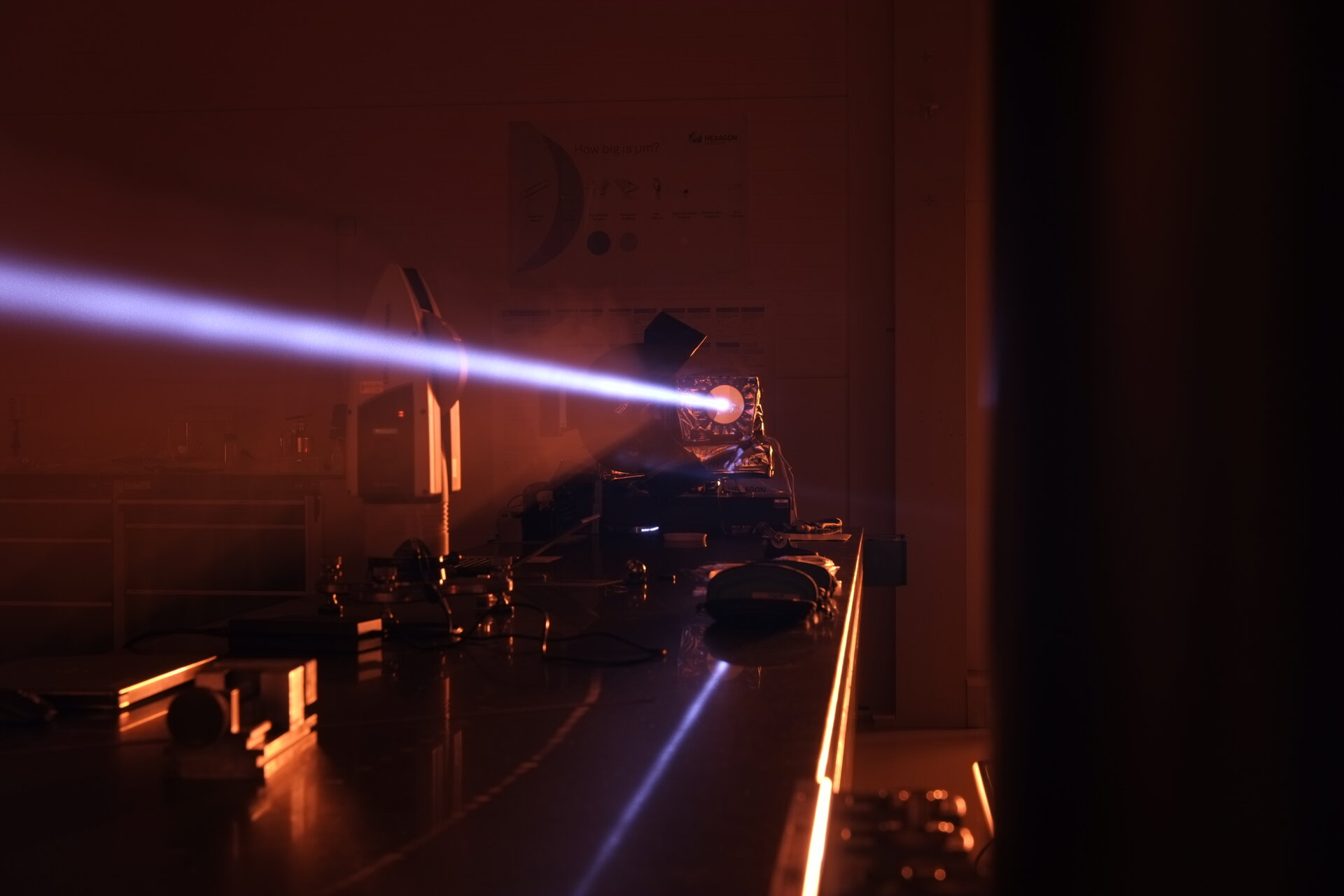

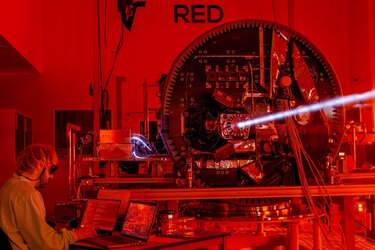

The double spacecraft of ESA’s Proba-3 mission will become the most precisely controlled objects in space, maintaining a set distance from each other down to millimetre-level precision. An ESA cleanroom was turned into a hall of mirrors to test the laser-based measuring system that will maintain the pair in position for hours at a time.

“Due to launch in 2024, Proba-3 is ESA’s precision formation flying mission,” comments Damien Galano, ESA’s Proba-3 project manager. “By maintaining their relative position against one another for up to six hours per orbit at a nominal 144 m apart, the ‘Occulter’ spacecraft will cast a shadow onto its ‘Coronagraph’ counterpart to form an artificial solar eclipse in space, so that the Sun’s faint outer atmosphere or corona can be studied freely.

“But the satellite pair require a sophisticated metrology system to hold them in position – and we needed to test the flight hardware of the most precise element of this multi-faceted system, the laser-based ‘fine optical metrology’ system.”.

The project requested support from the Metrology Laboratory of ESA’s ESTEC Test Centre in the Netherlands, part of the biggest satellite test facility in Europe, operated for the Agency by European Test Services. The Lab's Ramon Vink explains: “Our challenge was to find a cleanroom long enough to encompass the full range of distances involved for the laser and its retroreflector, as far as 250 m apart.”

The team settled on the Vacuum Test Chamber-1.5 cleanroom, adds Steven Sablerolle of the Metrology Lab: “At 60 m in length the VTC-15 cleanroom was too small, so instead they installed a folding array of mirrors that could bounce the laser beam around the chamber to cross the full range of distance required.”

Jorg Versluys, Proba-3 System Engineer, says: “The Test Centre’s Metrology Lab assisted us in precisely aligning and mapping the mirrors’ positions, using their own laser trackers. The test campaign took about six weeks, mostly during the night to minimise unwanted perturbations from the rest of the busy site – even a lorry driving past on the road outside might show up in our results. This testing marked the first time the various parts of this fine optical metrology system were operated together, but the results were right in line with our previous models.”

For the testing, Proba-3’s laser-generating optic head was integrated onto the mission’s optic bench, then placed on a granite table for maximum stability. The laser was shone onto a laser retroreflector – which is a special kind of mirror, resembling reflective ‘cat’s eyes’ on a motorway, that possesses carefully-designed internal reflectivity to bounce back the laser light in the exact same direction that it has come from.

A photo diode on the optic head then recognises reflected laser light to calculate the number of wave oscillations the light has taken to bounce back, to derive its precise travel time and therefore distance between the two satellites. A second detector, a 2D array, is acquires the lateral position of the reflected laser beam to identify the lateral displacement of the retroreflector relative to the optic head.

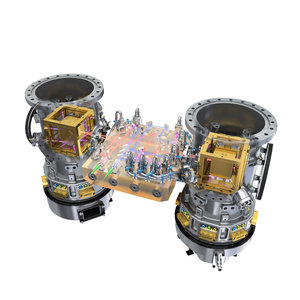

This is the most precise of multiple metrology methods employed by the two Proba-3 satellites, each one around a cubic metre in scale. A continuous inter-satellite radio link is supplemented by Global Navigation Satellite System receivers. When the satellites come less than 250 m apart then cameras on the Occulter spacecraft will image and detect LEDs mounted on the Coronagraph spacecraft. Then the laser-based system will come into use to maintain precise satellite alignment.

“Our testing allowed us to map just how the metrology system responds as the target moves slightly up or down or side to side,” adds Jorg. “So we’ve ended up with a complete database of the two units’ movement down to pixels per millimetre scale that we can employ for real when we reach space.”

Proba-3’s laser operates at an infrared wavelength, invisible to the naked eye. So this photograph was actually acquired as a long exposure in infrared, with the path of the beam gradually traced using a sheet of white paper. The beam seen in the photo is where the paper scatters the infrared light of the laser beam.

Proba-3's laser metrology has been developed by a consortium of European companies: MDA in the UK, Micos Engineering in Switzerland and AMOS in Belgium, with SENER Aerospace as prime contractor.

-

CREDIT

ESA - J.Versluys -

LICENCE

ESA Standard Licence

Proba-3's laser-precise positioning

Proba-3: Firing laser!

LISA Technology Package

Proba-3’s orbit

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland