Accept all cookies Accept only essential cookies See our Cookie Notice

About ESA

The European Space Agency (ESA) is Europe’s gateway to space. Its mission is to shape the development of Europe’s space capability and ensure that investment in space continues to deliver benefits to the citizens of Europe and the world.

Highlights

ESA - United space in Europe

This is ESA ESA facts Member States & Cooperating States Funding Director General Top management For Member State Delegations European vision European Space Policy ESA & EU Space Councils Responsibility & Sustainability Annual Report Calendar of meetings Corporate newsEstablishments & sites

ESA Headquarters ESA ESTEC ESA ESOC ESA ESRIN ESA EAC ESA ESAC Europe's Spaceport ESA ESEC ESA ECSAT Brussels Office Washington OfficeWorking with ESA

Business with ESA ESA Commercialisation Gateway Law at ESA Careers Cyber resilience at ESA IT at ESA Newsroom Partnerships Merchandising Licence Education Open Space Innovation Platform Integrity and Reporting Administrative Tribunal Health and SafetyMore about ESA

History ESA Historical Archives Exhibitions Publications Art & Culture ESA Merchandise Kids Diversity ESA Brand Centre ESA ChampionsLatest

Space in Member States

Find out more about space activities in our 23 Member States, and understand how ESA works together with their national agencies, institutions and organisations.

Science & Exploration

Exploring our Solar System and unlocking the secrets of the Universe

Go to topicAstronauts

Missions

Juice Euclid Webb Solar Orbiter BepiColombo Gaia ExoMars Cheops Exoplanet missions More missionsActivities

International Space Station Orion service module Gateway Concordia Caves & Pangaea BenefitsLatest

Space Safety

Protecting life and infrastructure on Earth and in orbit

Go to topicAsteroids

Asteroids and Planetary Defence Asteroid danger explained Flyeye telescope: asteroid detection Hera mission: asteroid deflection Near-Earth Object Coordination CentreSpace junk

About space debris Space debris by the numbers Space Environment Report In space refuelling, refurbishing and removingSafety from space

Clean Space ecodesign Zero Debris Technologies Space for Earth Supporting Sustainable DevelopmentApplications

Using space to benefit citizens and meet future challenges on Earth

Go to topicObserving the Earth

Observing the Earth Future EO Copernicus Meteorology Space for our climate Satellite missionsCommercialisation

ESA Commercialisation Gateway Open Space Innovation Platform Business Incubation ESA Space SolutionsLatest

Enabling & Support

Making space accessible and developing the technologies for the future

Go to topicBuilding missions

Space Engineering and Technology Test centre Laboratories Concurrent Design Facility Preparing for the future Shaping the Future Discovery and Preparation Advanced Concepts TeamSpace transportation

Space Transportation Ariane Vega Space Rider Future space transportation Boost! Europe's Spaceport Launches from Europe's Spaceport from 2012Latest

Juice testing – down to the wire

Thank you for liking

You have already liked this page, you can only like it once!

Preparing the Juice mission to Jupiter has involved testing for all kinds of contingencies, down to the smallest of scales. This microscopic view shows surface damage to a tiny silver interconnector after being exposed to erosive atomic oxygen known to be found surrounding Jupiter’s moon Ganymede.

Due to launch on 13 April to begin an eight-year journey to the largest planet in the Solar System, ESA’s Jupiter Icy Moons Explorer, Juice, will spend three and a half years in the Jupiter system, and in the final phase of its exploration will go into orbit around the largest Jovian moon, Ganymede.

However previous observations by the Hubble Space Telescope have revealed auroral glows around Ganymede due to the presence of ‘atomic oxygen’ – individual atoms of oxygen at the fringes of the moon’s scanty atmosphere, the result of standard oxygen molecules being broken apart by the powerful radiation belts surrounding Jupiter.

ESA materials engineer Adrian Tighe explains: “Atomic oxygen is also experienced in Earth orbit, due to oxygen molecules being dissociated by ultraviolet radiation from the Sun, and all Earth-orbiting missions below about 1000 km altitude are designed to resist it. In the same way, the Juice team needed to know that susceptible materials could withstand the atomic oxygen the spacecraft would encounter in the mission’s Ganymede elliptical orbit phase.”

This test focused on silver interconnects used in the Juice solar arrays – connectors just a few tenths of a thousandth of a millimetre thick – looking into their susceptibility to atomic oxygen exposure combined with low-temperature ‘thermal cycling’ – repeated rapid temperature shifts. Of particular concern was the risk of microcracks forming in the silver, which might lead to failure.

“Silver is one of the very few metals susceptible to atomic oxygen erosion,” comments Sam Verstaen of ESA’s Juice team. “But silver was also the preferred metal for these Juice interconnects in order to maintain the spacecraft’s magnetic cleanliness which is essential for the optimal operation of our suite of in-situ science instruments.”

Testing was performed in the Low Earth Orbit Facility, LEOX, of ESA’s Materials and Electrical Components Laboratory, part of the Agency’s ESTEC technical centre in the Netherlands.

A one-of-a-kind facility in Europe, LEOX uses a laser to dissociate molecular oxygen into atomic oxygen at energy levels that are equivalent to orbital speed – 7.8 km/s – to simulate the space environment as closely as possible.

“The general effects of atomic oxygen exposure could be seen clearly on the sample interconnectors,” adds ESA materials engineer Gabor Milassin, who performed the testing. “However it was demonstrated that this was only a surface effect, and no major cracks were observed which could compromise the functionality of the interconnects – the silver interconnects could be given a clean bill of health to go to Ganymede.”

The Lab also worked on numerous other Juice-related tests, including evaluating multi-layer insulation, adhesive tapes and thermal control coatings. Juice presented particular problems in materials terms because the mission will pass from the high-temperature environment of a Venus flyby, where temperatures will rise above 200°C, down to a much colder environment around Jupiter.

To read more about how ESA’s Directorate of Technology, Engineering and Quality supported the preparation of the Juice mission, click here.

-

CREDIT

ESA-G. Milassin -

LICENCE

ESA Standard Licence

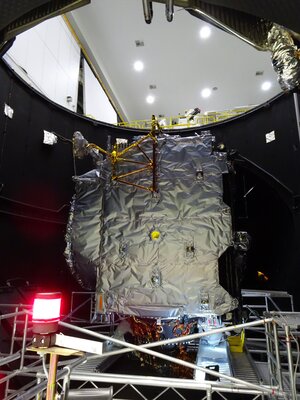

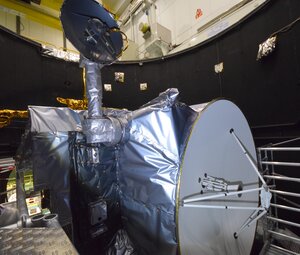

Juice in the Large Space Simulator

Thousands of thermocouples

Juice in the Large Space Simulator

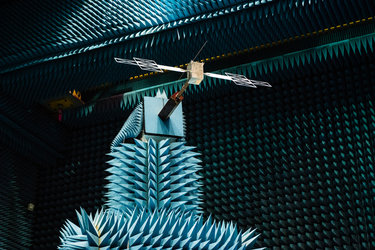

Juice antenna

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland