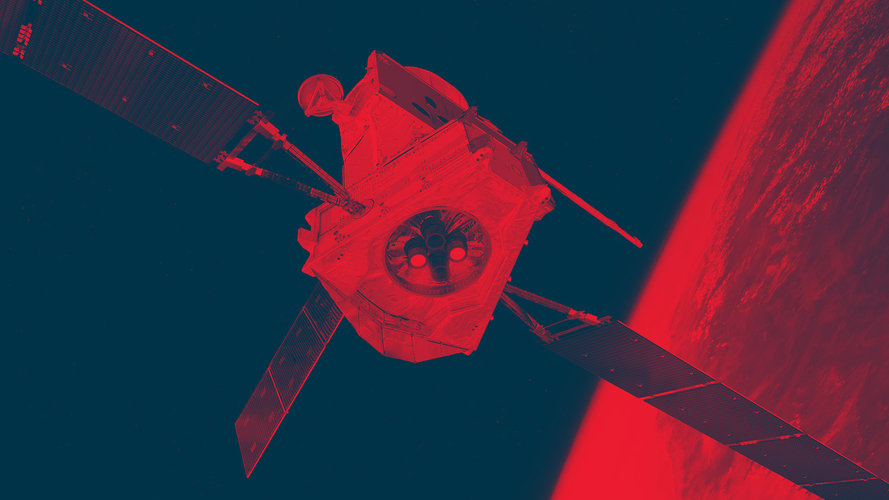

Electric blue thrusters propelling BepiColombo to Mercury

In mid-December, twin discs will begin glowing blue on the underside of a minibus-sized spacecraft in deep space. At that moment Europe and Japan’s BepiColombo mission will have just come a crucial step closer to Mercury.

This week sees the in-flight commissioning and test firing of the four thrusters – with one or two firing at a time – of the Solar Electric Propulsion System that BepiColombo relies on to reach the innermost planet. This marks the first in-flight operation of the most powerful and highest-performance electric propulsion system flown on any space mission to date.

Each thruster and its associated power processing and propellant flow control units will be tested to full power to check no ill-effects were incurred from launch, culminating in the first twin thruster operations – the configuration to be used throughout most of the mission.

Their first routine firing is scheduled for the middle of next month, and the propulsion system will operate continuously for three months to optimise the spacecraft’s trajectory for the long voyage to Mercury.

Access the video

The voyage inward

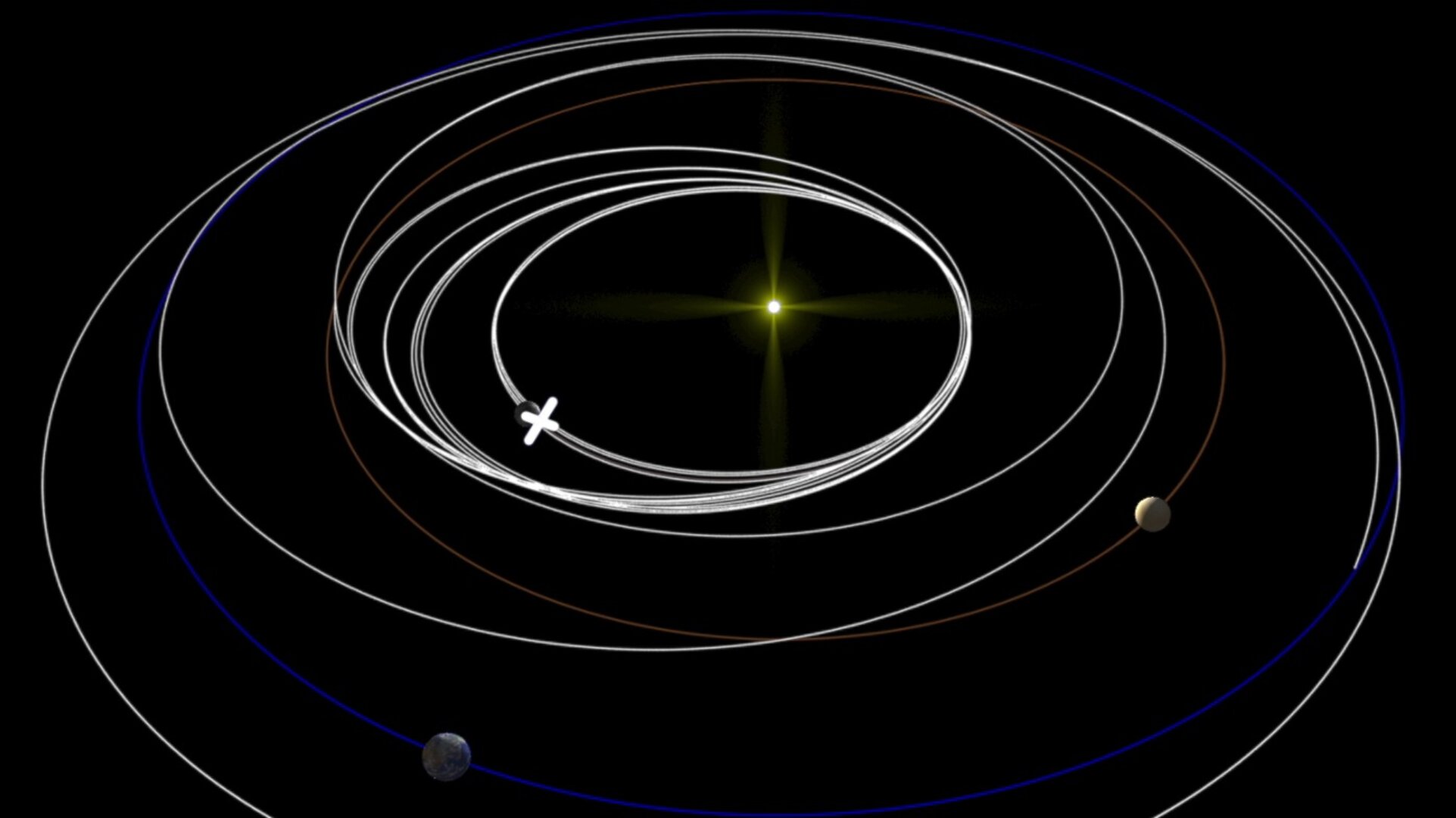

BepiColombo, launched from Europe’s Spaceport in French Guiana on 20 October, faces a different challenge from ESA planetary science missions before it: it is headed inward, toward the Sun, not out, and needs to lose velocity instead of gaining it.

Like all objects in the Solar System, the spacecraft is in solar orbit, moving perpendicular to the pull of the Sun’s gravity. BepiColombo therefore has to slow down through a series of braking manoeuvres and flybys, making it more susceptible to the Sun’s gravity and letting it spiral closer to the heart of the Solar System.

The thrust produced by the electric propulsion system serves to decelerate the spacecraft, or in some cases accelerates it to make its braking flybys more effective. No less than nine planetary flybys of Earth (once), Venus (twice) and Mercury itself (six times) are required to place the multi-module spacecraft in orbit around Mercury in seven years’ time.

Space tug

The Mercury Transfer Module portion of the spacecraft, containing the propulsion system, is in essence a high performance ‘space tug’. Its task is to perform all the active trajectory control manoeuvres needed to convey the other portions of the BepiColombo ‘stack’ – ESA’s Mercury Planet Orbiter and Japan’s Mercury Magnetospheric Orbiter – to Mercury orbit.

The high performance of the propulsion system, in terms of the amount of fuel the thrusters require, is critical. Inert xenon gas is fed in to the thrusters, where electrons are first stripped off the xenon atoms. The resulting electrically charged atoms, referred to as ions, are then focused and ejected out of the thrusters using a high voltage grid system at a velocity of 50 000 meters per second.

This exhaust velocity is 15 times greater than conventional chemical rocket thrusters, allowing a dramatic reduction in the amount of propellant required to achieve the mission.

“The propulsion system transforms electricity generated by the Mercury Transfer Module’s twin 15 m-long solar arrays into thrust,” explains ESA electric propulsion engineer Neil Wallace.

“At full power, a thrust equivalent to the weight of three 1-euro coins is developed, meaning that the thrusters have to keep firing for long periods to be effective, but in the absence of any drag and assuming you are patient, the manoeuvres that are possible and the payload that can be carried are dramatic.”

Electrifying spacecraft propulsion

The four T6 thrusters around which the solar electric propulsion system is designed, have a heritage dating back decades. QinetiQ in the UK – formerly the UK Defence Evaluation and Research Agency and before that the Farnborough Royal Aircraft Establishment – has been researching electric propulsion since the 1960s.

The first flight of their technology came with the 10 cm-diameter T5 thruster, a key element of ESA’s 2009 gravity-mapping GOCE mission, where it allowed the satellite to orbit at the top of Earth’s atmosphere for over three years, skimming through the diffuse atmosphere at the unprecedentedly low orbital altitude needed for the mission.

The scaled-up T6 thrusters are 22 cm in diameter, the increase in size required for the higher thrust and lifetime requirements of the BepiColombo mission. And unlike GOCE’s T5, these T6 thrusters are manoeuverable, courtesy of gimbal systems developed by RUAG Space in Austria.

Access the video

“They are clever mechanisms that complicate the system design a bit – all the electrical cables and pipes have to cross a moving boundary – but add a lot to performance,” adds Neil. “They ensure the thrust vector of either a single or double engine firing crosses through the centre of gravity of the spacecraft, which changes over time as propellant is used up.”

Thruster operations are controlled using two Power Processing Units, the architecture of which are designed to support the firing of two T6s simultaneously even in the event of any system anomaly, guaranteeing the maximum thrust of 250 mN can be maintained.

Injecting intelligence

“The intelligence of the system for autonomous thruster operation comes from these Power Processing Units – contributed by Airbus Crisa in Spain,” explains Neil, “which supply the regulated voltages and currents to the thrusters based on instructions from ground control via the spacecraft on-board computer.”

The other key elements are propellant Flow Control Units, also overseen by the PPUs, and the high-voltage electrical harness. The FCUs ensure the correct flows of xenon gas are supplied to the thrusters and were developed by Bradford Engineering in the Netherlands to provide programmable flow rates.

The various elements of the propulsion system have undergone individual and extensive performance and qualification testing ultimately concluding in a series of tests performed at QinetiQ's Farnborough site.

Testing times

The spacecraft configuration and the extreme nature of the BepiColombo mission – needing to function in thermal conditions akin to placing it in a pizza oven – often demanded similarly extreme test scenarios, pushing the solar electric propulsion technology and test facilities to their limits.

“One important test early in the programme was to ensure that two thrusters could be operated in close proximity for prolonged periods without harmful interactions,” adds Neil. “They turned out to be remarkably tolerant of each other with no measureable effects.”

One of the biggest ironies of the thruster qualification for BepiColombo, heading close to the Sun, was the extreme minimum temperatures experienced by its ion thrusters.

Neil explains: “Despite the fact the mission is headed to Mercury, the bulk of the spacecraft shadows the thrusters for very long periods and when not operating they naturally cool to temperatures way lower than ever tested in the past. We needed to prove they would turn-on and operate within specification when cooled to minus 150 C.

“It was a remarkable testament to the robustness of the technology that even after temperatures sufficient to freeze the xenon in the pipes the thrusters were able to start and operate flawlessly.”

End of the journey

The propulsion system is dependent on the Mercury Planetary Orbiter’s onboard computer for its control and command, so by itself it will not be able to function. Its ultimate fate is to be cast off, when the three-module BepiColombo stack separates before entering Mercury orbit, to circle the Sun indefinitely in the vicinity of the planet, letting the two science modules go to work.

“At one point while planning the BepiColombo mission, the Mercury Transfer Module was planned to impact the planet,” Neil comments, “a sort of Viking funeral that seemed fitting to all of us engineers.”

Gridded ion thruster technology will have a life far beyond BepiColombo however, with commercial applications in development, and future, even more ambitious ESA science missions set to rely on the technology.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland