To explore space means defying dust

As the world’s space agencies prepare to return to the Moon and explore the planets, space materials engineers have been getting to grips with a challenging enemy: dust. The abrasive, talcum-like dust enshrouding the Moon and other planetary surfaces can obscure surfaces, wear away at coatings and clog space mechanisms.

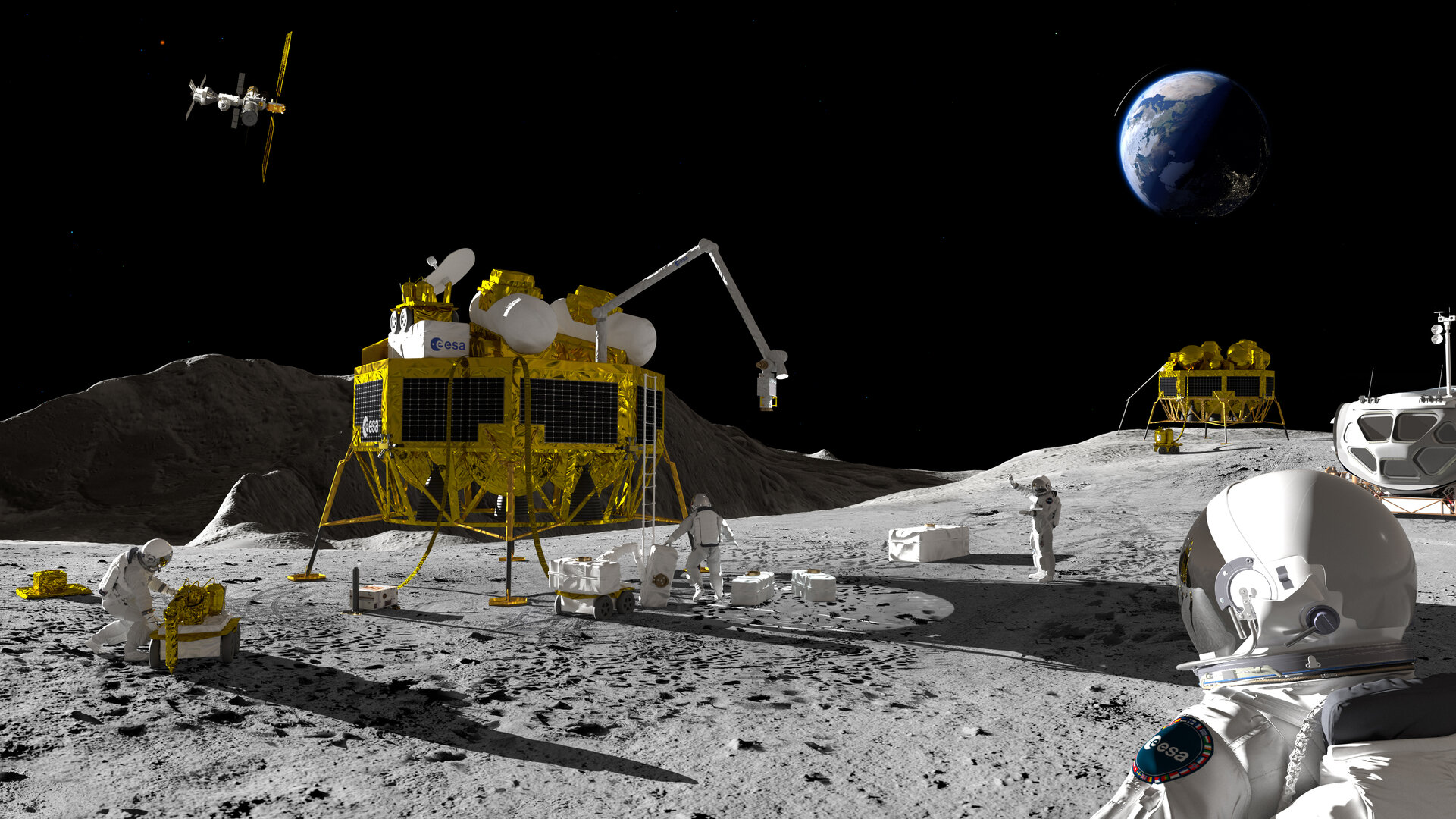

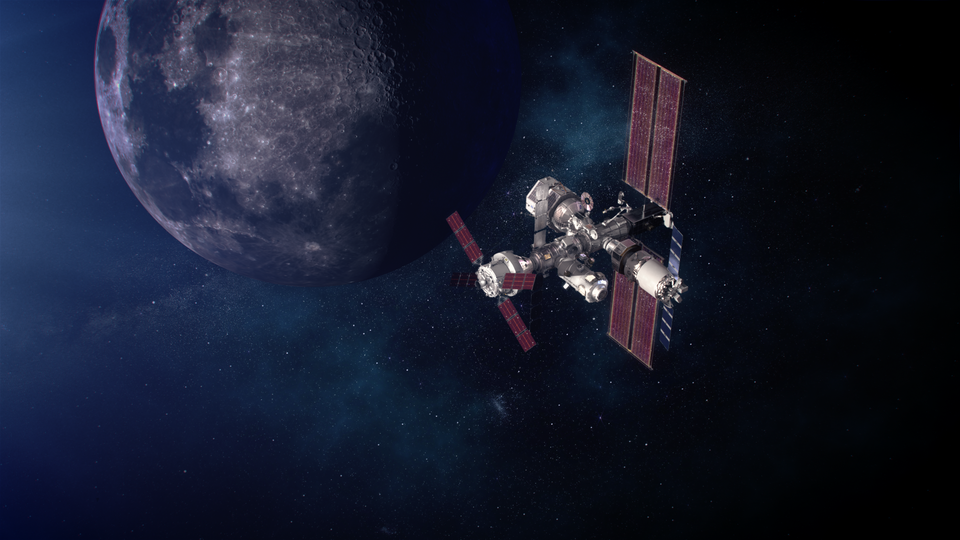

For ESA, dust contamination is an urgent issue for coming missions such as the international lunar Gateway – a planned station in lunar orbit including European modules, which will serve as a basecamp for sojourns down to the Moon’s surface – and the Argonaut European Large Logistics Lander, EL3, intended to transport cargo for lunar settlers, which would remain on the Moon for prolonged periods.

ESA is also responsible for the robotic Sample Transfer Arm of the international Mars Sample Return campaign – with the crucial role of taking samples from Mars rovers to place them on an ascent rocket for return to Earth. Dust could potentially interfere with the 2.5-m-long arm’s mechanisms.

The Agency’s materials engineers met with their international counterparts at the recent ISMSE-13/ICPMSE-15 Materials in the Space Environment conference at Leiden in the Netherlands, with dust control among the major themes under discussion.

They presented research including a dedicated Planetary Dust Simulation Facility – currently taking shape at ESA’s ESTEC technology centre in the Netherlands – which will be used to investigate charging effects and dust-induced thermal and optical shifts in surfaces. They have also been evaluating the effects of dust on spacesuit textiles and with actual moondust worth more than its weight in gold, they are evaluating the most suitable lunar simulants for test purposes.

Dust to dust – on the Moon and beyond

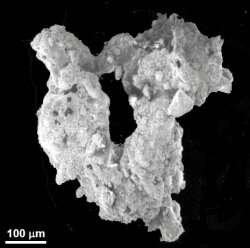

James Gaier, retired NASA scientist who worked on the Apollo programme, chaired a dedicated panel discussion at the conference. He noted that “Lunar dust is present all across the Moon, created by the steady bombardment of micrometeorites pulverising the rocky surface into fine particles. Unlike terrestrial dust it has never been weathered by water or wind, so that even microscopic particles still maintain edges of razor sharpness. And the unfiltered energy of lunar sunshine can impart the dust with serious static cling.”

Looking further afield, the same is true of the Martian surface – complete with wind to shift it around the planet – as well as rocky moons lacking atmospheres and many asteroids.

Apollo astronauts who encountered lunar dust first-hand during Apollo landings of up to a few days on the Moon’s surface highlighted the challenge it presents for longer-duration stays in their mission debriefs.

Apollo 12 Commander Pete Conrad noted: “I think probably one of the most aggravating, restricting facets of lunar surface exploration is the dust and its adherence to everything no matter what kind of material, whether it be skin, suit material, metal, no matter what it be and its restrictive friction-like action to everything it gets on.” He added that even spacesuit outer layers were starting to be worn through.

Apollo 17 Commander Gene Cernan agreed: “I think dust is probably one of our greatest inhibitors to a nominal operation on the Moon. I think we can overcome other physiological or physical or mechanical problems except dust.”

More recently, China’s Yutu-1 rover is believed to have been immobilised during its second day on the Moon by lunar dust clogging its moving parts.

Dusty lunar touchdowns

Terming lunar dust contamination as unfinished business from Apollo, Carlos Soares of the Contamination Control Engineering team at NASA’s Jet Propulsion Laboratory (JPL) explained that the problem begins during touchdown – depending on the size of lander involved, its rocket thrusters could dislodge tonnes of lunar regolith during touchdown, which might then lodge on lander surfaces as well as covering the entire landing area.

JPL has therefore developed a complex modelling-based framework to simulate lunar landing events, starting with recreating Apollo landings, to help enable degradation assessments. To help validate these simulations, thruster plume testing has been performed using the German Aerospace Center’s high vacuum plume test facility STG-CT. The framework has also been applied to other planetary landing scenarios, including a touchdown on Europa, the ice-encrusted moon of Jupiter.

A team led by Italy’s National Aerospace Research Centre (CIRA) also presented their work on developing a specially tailored dust-proof polymer, with surface properties modified to form ‘non-stick’ surfaces.

Novel space environments and issues

Co-organised with French space agency CNES French aerospace lab Onera, and the Integrity Testing Laboratory Canada, ISMSE-13/ICPMSE-15 on 18-23 September marked the first time that the international space materials engineering community had gathered in person for four years, joined by participants from the Japan Aerospace Exploration Agency JAXA and the China National Space Administration (CNSA) as well as national space agencies.

ESA materials engineer and co-organiser Adrian Tighe explains: “In one form or another this event has been running for four decades now, where we get together to discuss many of the problems the space sector is currently grappling with in terms of the space environment and its effect on materials.

“So as well as the dust topic, we saw for instance a focus on issues arising with satellites flying really close to Earth – at so-called ‘Very Low Earth Orbit’ altitudes – where highly erosive atomic oxygen encountered at the top of the atmosphere could be an issue for planned constellations as well as the challenge of simulating orbital debris damage at a materials level, which is proving an increasingly significant factor in highly-trafficked orbits.

“Then there’s the growing trend around commercialisation, including the wish to use more ‘commercial off the shelf’ parts for cheaper, faster space missions, in place of traditional space-qualified components and materials – but requiring a balancing act in terms of performance, radiation tolerance and so on. Then came discussions on whole new manufacturing and testing methodologies based on concepts such as digitalisation and modelling, artificial intelligence and machine learning, opening up lots of novel possibilities!”

ISMSE-13/ICPMSE-15 was hosted at Leiden’s Naturalis Biodiversity Centre, making possible a fascinating talk on the preservation process of dinosaur bones before they are put on display, and lending context to a discussion on ‘biomimetics’ for space – mimicking natural systems and lifetimes for engineering purposes.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland