Electromagnetic Levitator turns ten

This summer marks the ten-year anniversary of the electromagnetic levitation facility on the International Space Station.

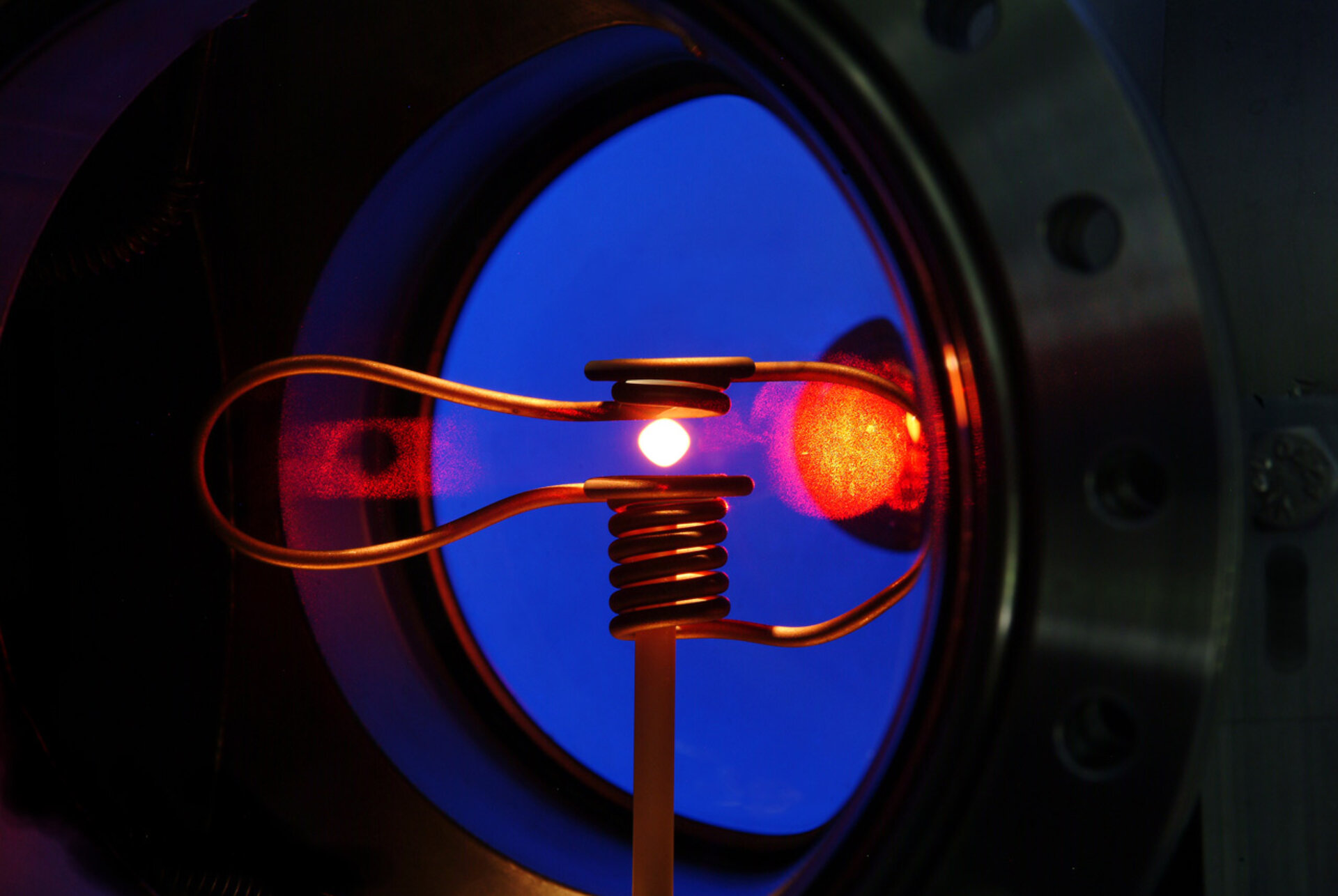

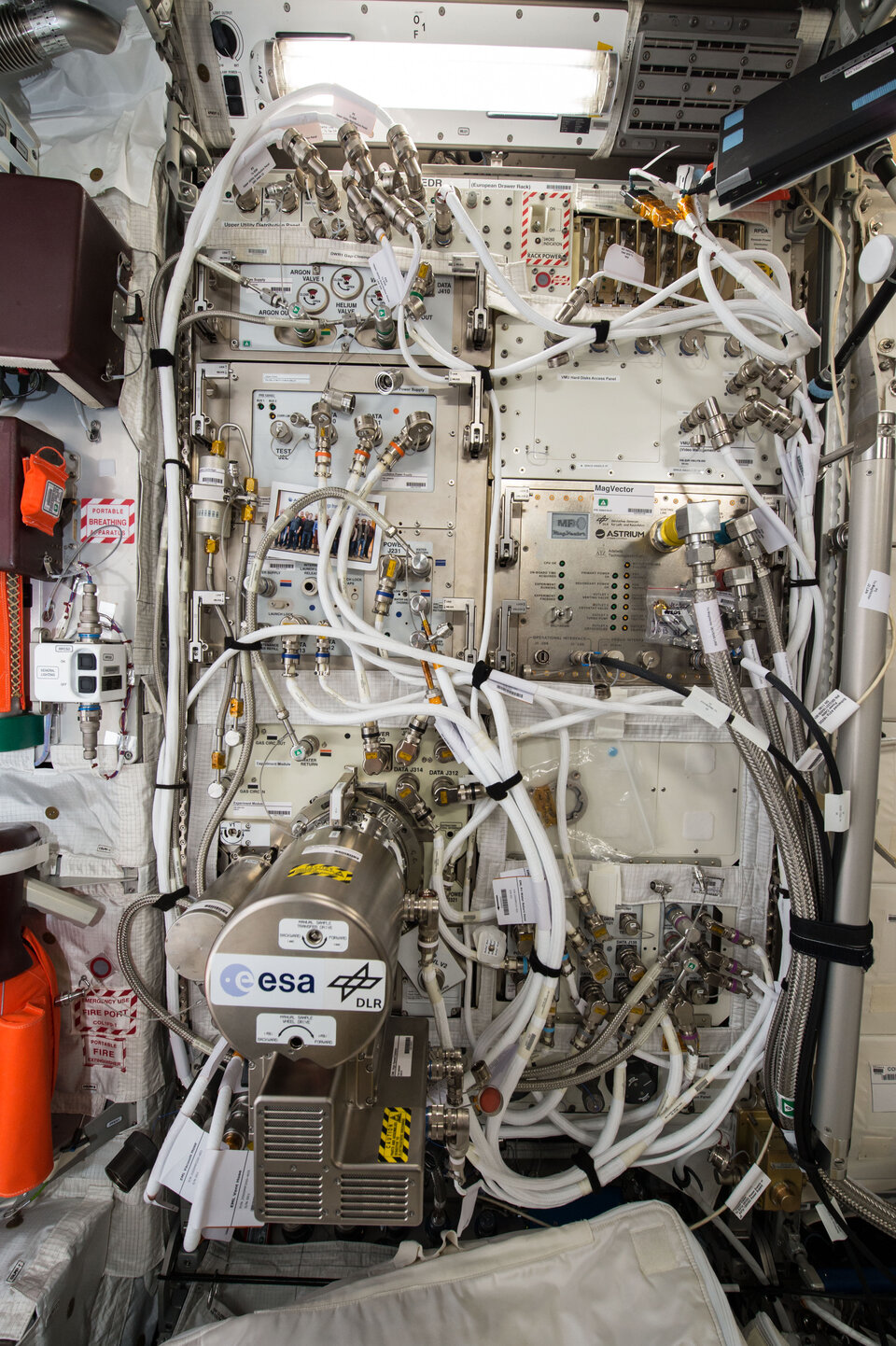

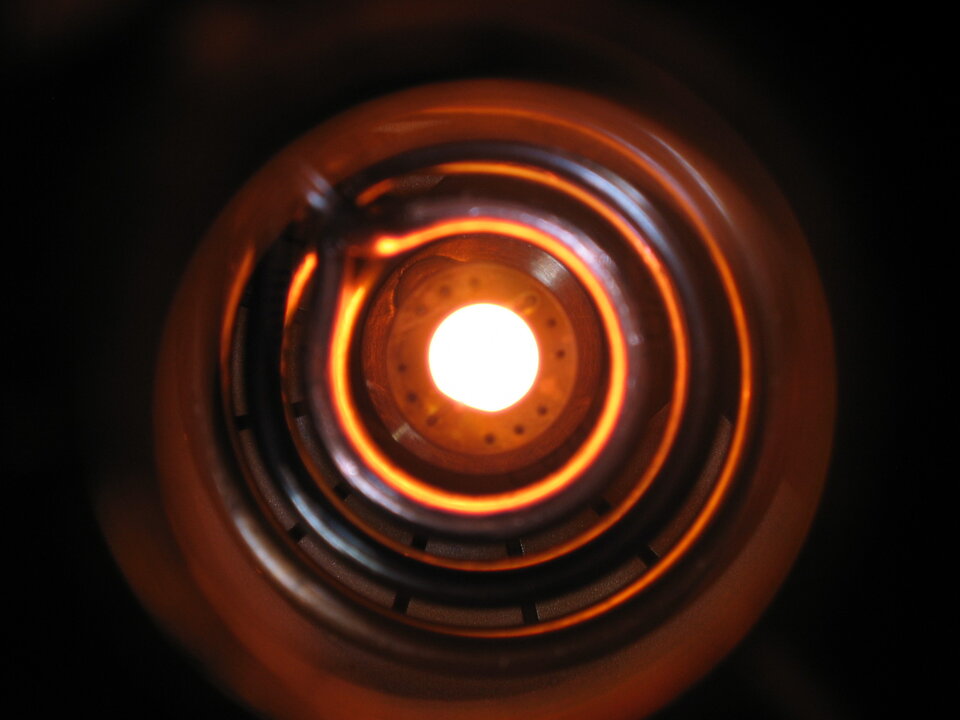

Helping to reveal the core physics at play in materials science, the Electromagnetic Levitator (EML) is a furnace in ESA’s Columbus laboratory that can melt metals by heating them up to 2200 °C. Scientists can then observe the samples in a molten state, or while solidifying in weightlessness as they cool rapidly. On Earth, this process is influenced by gravity and the sample’s contact with the walls of the furnace.

The fifth and last Automated Transfer Vehicle brought EML to the International Space Station in the summer of 2014. ESA astronaut Alexander Gerst installed the facility during his Blue Dot mission and EML has been hosting science experiments ever since.

A brief history

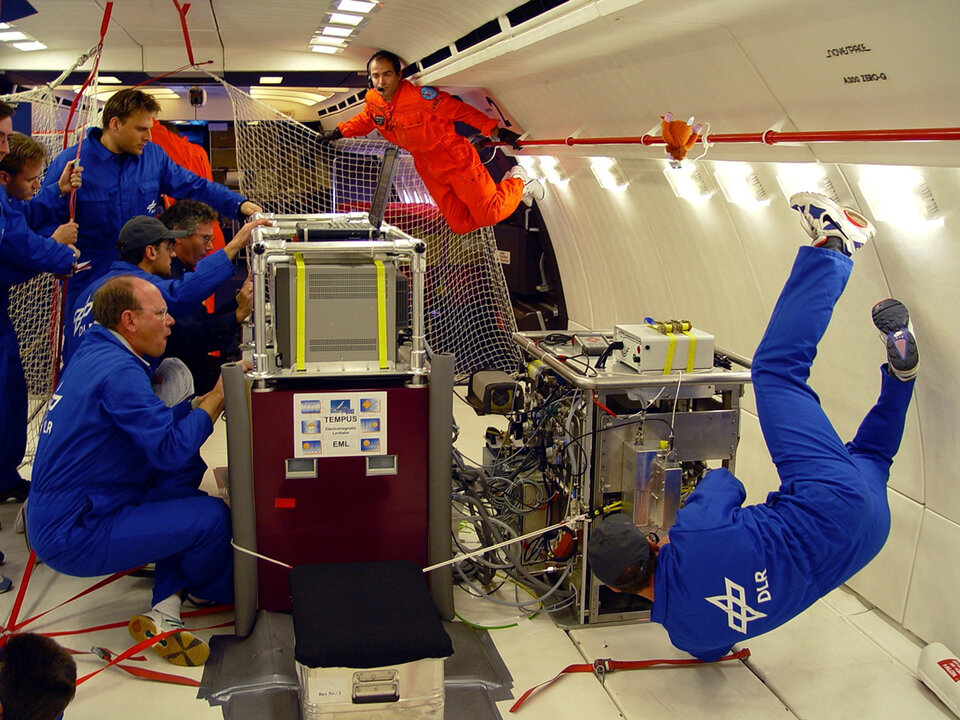

The electromagnetic levitation technology has been tested using low gravity platforms since the 1980s, first on parabolic flights and sounding rockets and then on Spacelab, Europe’s laboratory on the Space Shuttle. These platforms offered increasing amounts of time in reduced gravity to material scientists and the International Space Station was the next logical step.

EML was sent to the Station in 2014; due to its size, the module had to be separated into different components prior to launch, some of them the size of washing machines. Alexander Gerst had to assemble EML inside the Columbus module. During this procedure, a bolt became lodged; he improvised by sawing through the screw, cleverly using shaving foam to contain metal debris within the microgravity environment.

“Installing the Electromagnetic Levitator presented certain challenges, but with great teamwork between space and ground teams, a little 'McGyver-ing' and a rather unusual tool we overcame them all. Switching it on was a big moment for me. It's great to see this facility still going strong, exploring metal alloys for the technologies of tomorrow,” says ESA astronaut Alexander Gerst.

Co-developed by ESA and the German Space Agency (DLR), designed, assembled and tested by European industry led by Airbus Defence and Space, EML has now been in operation for a decade, commanded from the Microgravity User Support Center (MUSC) in Cologne, Germany.

Science time

The research aims to better understand the properties of materials on the very small scale to construct precise models of how these materials behave on the larger scale.

EML helps scientists study the solidification processes of materials such as alloys, blends of materials selected to offer the best attributed of their parts. This improved understanding of materials could lead to optimisations within the manufacturing industry, from the creation of new and more efficient materials to refining casting processes such as 3D printing.

These materials science studies can be performed on Earth, but EML is particularly useful as it allows scientists to study samples with the least possible interference, from either gravity or the material’s contact with its surroundings. Scientists from all over the world can benefit from these special conditions. Every few years, a batch of 18 samples is selected to fly to the Station, where an astronaut loads them into EML on a revolver-like carousel. The microgravity furnace processes each sample and records the material and fluid behaviour with a high-speed camera and various sensors, before sending the data to MUSC and science teams.

“Being a materials scientist myself, the wonderful Electromagnetic Levitator was very close to my heart. When a gas circulation pump needed to be replaced during my Cosmic Kiss mission, I happily took on the task to keep this excellent facility running,” shares ESA astronaut Matthias Maurer.

EML has already been in use for a decade and was designed to work for several more years. In the last decades, over 700 publications have resulted from the experiment and its heritage, with a large majority appearing in top materials science journals.

The experiment has enhanced scientists’ understanding of a large variety of materials, from aluminium and steel for construction purposes, and semiconductors crucial for modern electronics, to high-performance materials designed to endure extreme conditions, such as turbine engines and titanium alloy hip replacements.

The journey continues

EML is currently working with its third batch of samples, with a fourth batch ready to be sent to the Station and a fifth batch being prepared by scientists. A new module containing an oxygen control system for the instrument will be launched and installed by a crew member next year, allowing scientists to precisely measure and control the oxygen content of the EML process environment.

ESA is hosting an event on 22 May to celebrate the ten-year anniversary of EML with DLR and the scientific community using the facility.

Access the video

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland