Cooling aluminium alloy research

The CETSOL-2 series of experiments uses ESA’s Materials Science Laboratory on the International Space Station. Nothing less than a miniature metal furnace in space, the Materials Science Laboratory can heat samples to 1400°C before letting the metals solidify. Astronauts collect data for the MICAST ( Microstructure Formationin Casting of Technical Alloys) experiment by installing cartridges with metal alloys.

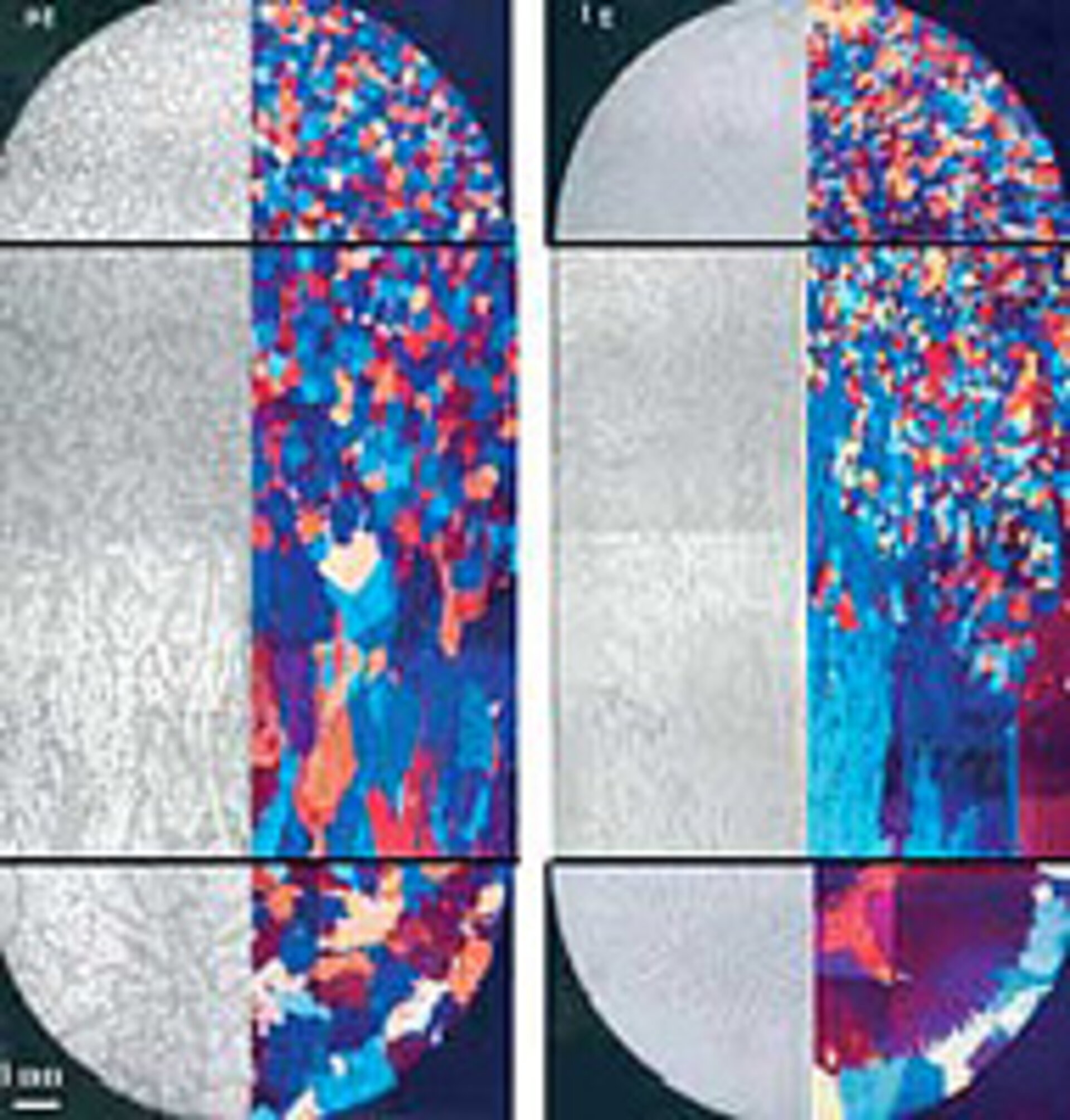

CETSOL-2 (Columnar to Equiaxed Transition in Solidification Processing) focuses on how cooling aluminium alloys in specific areas and adding microparticles can improve the result.

Aluminium is used in many products, from car engines to industrial machines but casting strong forms is heavily influenced by temperature differences during the cooling process. In a single block of cast aluminium, the strength, elasticity and resistance can differ because the aluminium does not cool uniformly.

This problem has been known for years but an effective computer model to use as a basis for improving the process has been missing.

In addition to looking at temperature, CETSOL-2 observes how adding microparticles can help. Like adding raisins to a cake-mix, adding small particles to a metal can improve the result. Called ‘grain refiners’ by metallurgists, these grains improve the metals properties but CETSOL-2 will help to understand how.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland