Metal alloy research

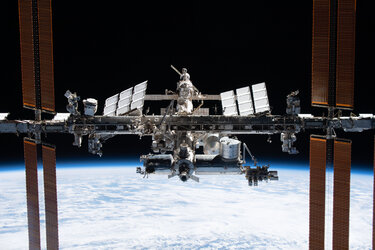

The MICAST-2 series of experiments uses ESA’s Materials Science Laboratory on the International Space Station. Nothing less than a miniature metal furnace in space, the Materials Science Laboratory can heat samples to 1400°C before letting the metals solidify. Astronauts collect data for the MICAST ( Microstructure Formationin Casting of Technical Alloys) experiment by installing cartridges with metal alloys.

The alloys are heated and solidified to study the microscopic structure of the resulting metal. A rotating magnetic field can be applied to increase the mixing. The goal is to understand the microstructure of alloys and how this changes under different casting conditions.

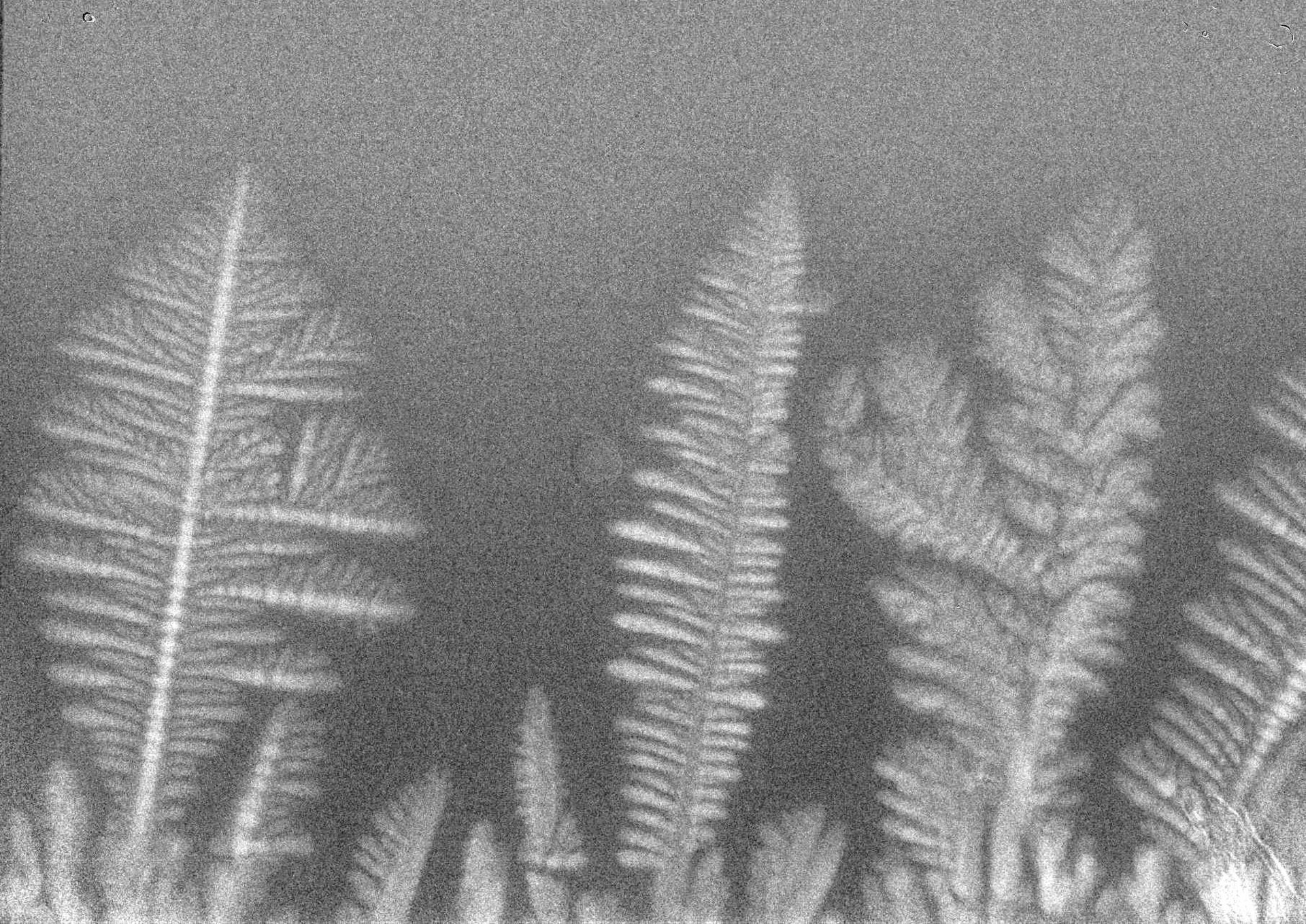

Researchers are particularly interested in controlling tree-like microstructures called dendrites that form during the solidification process. Controlling the number of dendrites in a metal can change properties such as elasticity.

Researchers examine growth patterns and evolving microstructures as samples of metallic alloys crystallise. The results will complement computer simulations and help to produce more efficient aluminium alloys for the transport industry.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland