Setting sail for sustainable space

Space is getting crowded. Old satellites, rocket bodies and fragments of both are leaving little space for new satellites to reside in that is free from debris.

The risk of collision with debris and even functioning satellites is increasing, especially in low-Earth orbit, putting many of Earth’s climate, ocean and land monitoring missions in harm’s way.

ESA is working alongside private business to clean up space by developing new missions and technologies that will remove debris from orbit. No space agency or business could solve the debris problem alone, but if it becomes technologically feasible – and profitable – to take care of our space environment, it will be much easier to do so.

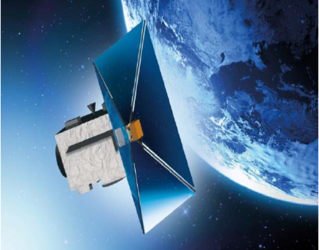

ESA’s General Support Technology Programme and the space technology company HPS GmbH are working together to do just this, by developing ‘drag sails’ known as the Drag Augmentation Deorbiting Subsystem (ADEO).

In this Q&A, Tiziana Cardone, ATG for ESA Structural Engineer of ADEO, and Daniel Stelzl, Head of Deployable Sails & Nanosatellites at HPS, explain how ESA is teaming up with industry to set sail for the sustainable use of space.

What is your role in the ADEO project?

Tiziana: I coordinate and support the development of the ADEO ‘drag sail’ for ESA and work closely with HPS on both the management and the technical aspects of the project. I initiated ADEO in 2012 and have followed every step of its development since.

Daniel: HPS is leading the development of the ADEO drag sail technology. We began developing spacecraft sails in 2000, originally for use in solar sail propulsion systems, and now to help ensure a sustainable future for space missions.

How does a drag sail work?

Tiziana: Spacecraft in low-Earth orbit will naturally fall to Earth as their orbits decay due to the drag force they experience from the atmosphere. But the drag force is not that high most of the time for spacecraft in orbits higher than 400 kilometres, and when these satellites have completed their mission, they don’t fall as quickly as we would like. In this case, a drag sail helps the spacecraft to ‘catch’ more of the atmosphere by greatly increasing its cross-sectional area. This helps it descend faster and burn up in the atmosphere sooner.

Daniel: If a spacecraft is still functional at the end of its mission, the drag sail subsystem receives a signal to begin its deployment from spacecraft operators on Earth. If not, a mounted battery and an internal computer program decide autonomously when to deploy. Our largest ADEO-L sails can be as big as 100 square metres – the size of a nice apartment – and take up to 45 minutes to deploy. The smallest ADEO-N sails are 3.5 square metres and deploy in just 0.8 seconds!

The ADEO sails vary greatly in size and can be fitted on spacecraft weighing up to 1500 kg. How do you decide what size sail a mission needs?

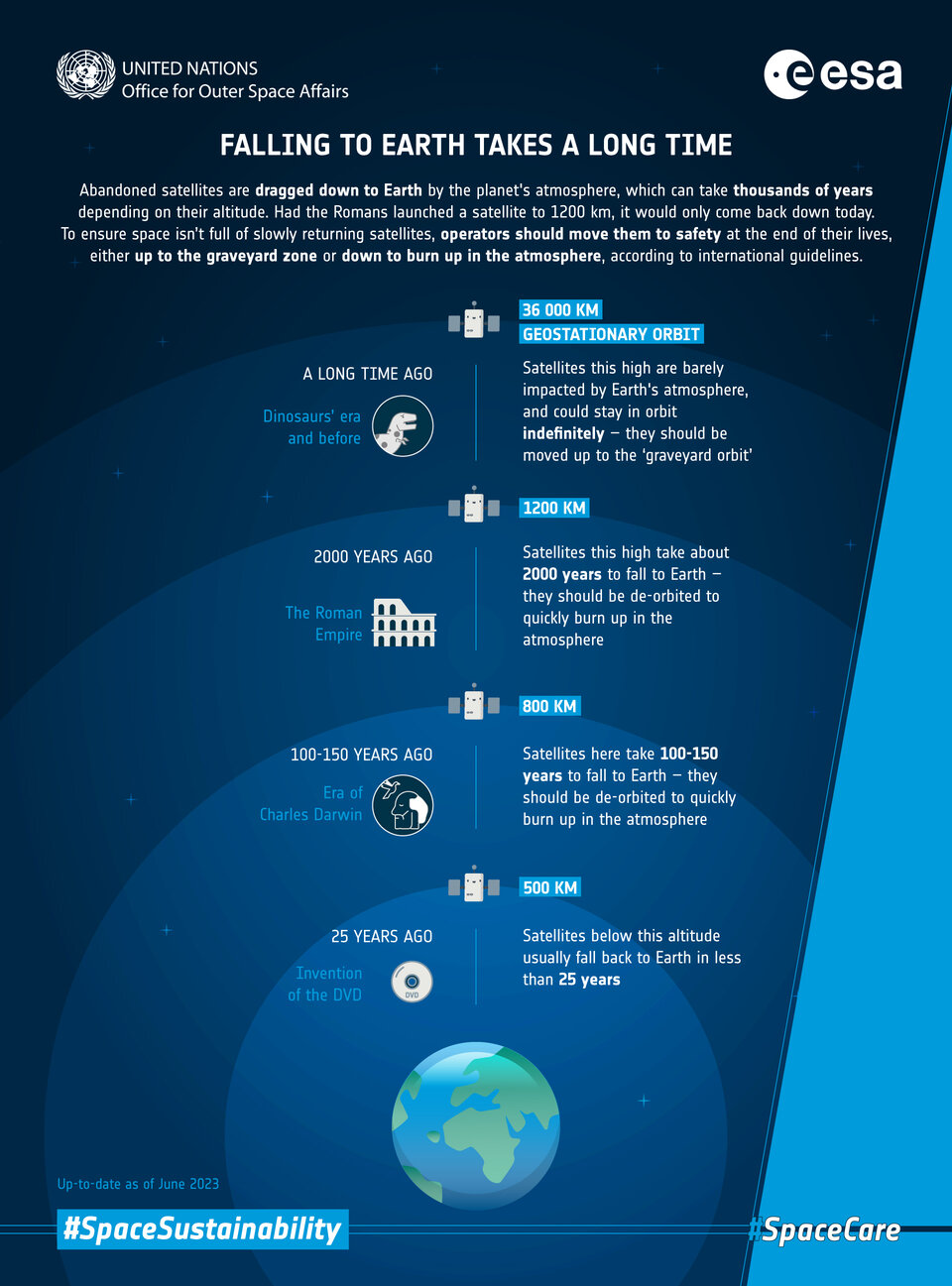

Tiziana: In general, the more massive the spacecraft, the larger the sail you need as it takes more drag force to speed up its descent – like how a heavier car needs stronger breaks to slow down. The size of the sail is decided with the spacecraft’s operator, but a very important factor is assuring compliance with the space debris mitigation guidelines.

These state that all spacecraft in low-Earth orbit should be designed to re-enter Earth’s atmosphere within 25 years of the end of their mission, to reduce the risks associated with space debris. So, at the very least, you need to use a sail that generates enough drag to bring the spacecraft down in that time.

Some spacecraft, however, are designed to re-enter much sooner than the international guidelines require. This allows the spacecraft operator to free up the very useful orbit the spacecraft was occupying and fill it with their next spacecraft as quickly as possible. For a quicker descent, you need a bigger sail!

What are the sails made of and how thick are they? They look like kitchen foil!

Daniel: They do, but they are much stronger. The sail is made from an aluminium-coated polyimide foil with a total thickness of just 7.5 micrometres – that’s about one tenth the thickness of an average human hair! We are constantly improving our design and studying other materials that could help make the sails stronger and thinner and even transparent.

How strong is the force acting on the drag sail from the atmosphere?

Tiziana: At higher altitudes where the atmosphere is thinner, the force on the drag sail starts off reasonably gentle. At lower altitudes though, it can get very strong, especially considering how thin the material is. If you’ve ever wrestled with a large kite on a windy day, you’ll have a good idea.

How do you fold up such a huge area of material in a way that allows it to ‘spring’ open in space?

Tiziana: A ‘Hold Down and Release Mechanism’ – used for lots of things in spacecraft – keeps the ADEO sail securely folded away in a box until it’s time to spring into action. When it’s time to deploy, either the spacecraft or the on-board battery will switch on a small motor.

The motor begins the deployment of the four carbon fibre reinforced booms to which the sail is attached – like the sticks holding the fabric of a kite in shape. As the booms deploy, they remove the sail’s protective insulation, freeing it from its box at which point it unfurls.

What does it mean that the sails are ‘passive’?

Tiziana: ADEO is passive as it doesn’t need any support from guidance, navigation and control systems to operate. Even if the spacecraft is tumbling out of control – which it almost certainly will be at the moment of deployment – we do not need to stabilise it to safely deploy the sail. We have specially designed the booms and the interface that connects them to the sail to ensure they are very resistant to the strains caused by tumbling.

Have ADEO drag sails already been successfully used in space?

Daniel: They have! A 2.5-square-meter ADEO-N sail was fitted on the ‘Electron kick’ stage of RocketLab’s ‘It’s Business Time’ mission in 2018, and another was tested during a parabolic flight campaign in 2019. In June 2021, an ADEO-N sail will be mounted on the 220-kilogram ‘ION Platform’ from D-Orbit S.p.A, which will be launched on a Falcon9 by SpaceX.

After about six months, the ADEO-N will deploy its 3.5-square-metre drag sail and the spacecraft will begin to de-orbit. An in-orbit demonstration of a larger ADEO-L sail is scheduled for an EU mission next year.

How do you find the partnership between ESA and HPS?

Tiziana: We work together great as a team. HPS is flexible and highly motivated; ESA is always ready to help analyse any unforeseen challenges, find solutions and provide support across all of the technical disciplines involved in the project.

Our partnership has already proved very successful and we will show this to the entire world with our upcoming in-orbit demonstration. Stay tuned, because you will hear a lot about ADEO in the coming months!

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland