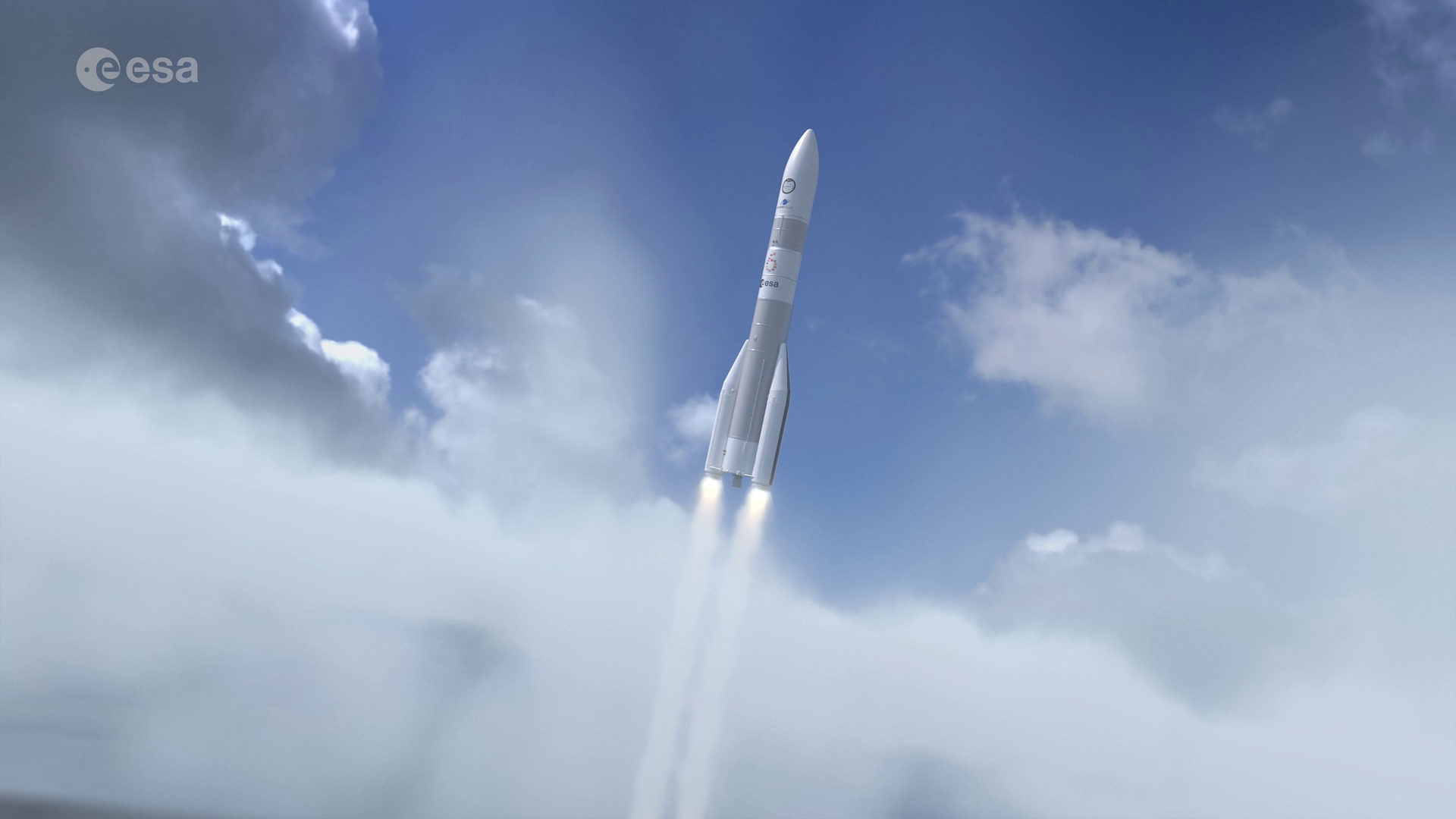

Assembling Ariane 6 for launch

Ariane 6 elements are made in Europe, shipped across the Atlantic as complete stages and then assembled at Europe’s Spaceport in French Guiana where the solid rocket boosters are completed and integrated to form the complete rocket on the launch pad.

The elements arrive by Canopée sailboat in the harbour of Kourou, French Guiana, where they are offloaded and moved by truck to their specific assembly halls.

The main stage is connected to the upper stage horizontally in the launch vehicle assembly building that is 20 m tall, 112 m long, and 41 m wide. The upper stage arrives first with the main stage then slotting into position, connecting the two to form the central core.

Access the video

The core is then transported to the Ariane 6 mobile building 1 km away, where a crane lifts the upper stage to bring Ariane 6 upright for the first time, the rocket is also now in position for launch. The mobile building surrounding Ariane 6 is a 90-metre-high metallic structure that rolls away on rails once assembly is complete to allow Ariane 6 a clear view of the sky and space. The building has platforms for technicians to further assemble Ariane 6 while also protecting the rocket until it is ready for launch.

The booster structures are produced in Italy and then filled with solid propellant at Europe’s Spaceport at their booster finishing facility at Europe’s Spaceport. They are transported to the mobile building and connected to the Ariane 6 next. Two or four boosters are connected to the core stage depending on the mission profile and energy needed to reach the targeted orbit.

A rocket is pointless without a cargo, which is why they are called payloads, it’s what is paid for to send to space. The payloads can arrive by ship or airplane – Ariane 6 can launch everything from satellites to constellations and huge spacecraft such as Moon landers – different cargo has different shipment needs. Payload preparation facilities at Europe’s Spaceport prepare the cargo for launch and connects everything to a payload adapter to fit onto Ariane.

Access the video

Once complete the payloads are put under a protective nose cone. This so-called fairing for Ariane 6 will ensure the cargo is kept at a nice ambient temperature and humidity while also protecting it from the elements. It also provides a sleek aerodynamic shape to help Ariane 6 overcome the atmosphere as it thunders upwards to space.

With the central core and boosters ready and connected, the payloads can be loaded to the top of the rocket, the complete nosecone with cargo is then moved to the mobile building and placed on top of the Ariane 6 launcher to complete the integration sequence.

A few hours before launch, the mobile building rolls away, and the complete Ariane 6 is fuelled up and prepared for the final countdown to liftoff.

Access the video

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland