The engines of Ariane 6

Not one, but three types of engines are needed to propel the Ariane 6 rocket and its passengers away from the clutches of gravity and into space. Let’s look at the astounding amount of thrust these marvels of engineering produce.

Boosters

Ariane 6 comes with boosters that produce thrust each that is equal to more than 35 jet engines. Every Ariane 6 has at least two boosters, and an Ariane 6 can be equipped with four, depending on the weight and destination of the satellites it pushes into space.

The boosters consume 142 000 kg of solid propellant in just over two minutes, like fireworks, once the boosters are ignited there is no going back, the engines will consume their solid propellant until they run out of fuel.

The boosters are developed by Europropulsion, owned by Avio and ArianeGroup and their industrial partners in Europe that design and build the Vega and Ariane 6 rockets. They are used for Ariane 6 as well as in the first stage of Vega, ESA’s rocket for smaller payloads.

P120C boosters main characteristics

- 142 000 kg of solid propellant

- 130 seconds of operation

- 3500 kN of thrust

- Altitude at shutoff: 53 km

Access the video

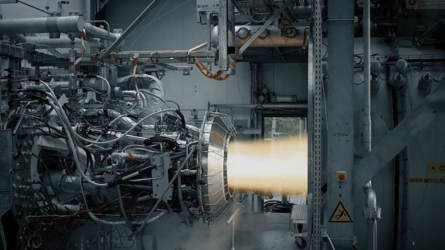

Vulcain 2.1

Vulcain 2.1 is the main stage engine and sits at the bottom of the Ariane 6 core. Calling Vulcain an engine hardly does it justice, this rocket engine uses liquid oxygen and hydrogen as fuel, providing more than 1370 kN of thrust.

The temperatures involved in operating the Vulcain 2.1 are extreme, it feeds itself from liquid hydrogen at –253° C and liquid oxygen at –183°C. These liquids are heated by passing them around the combustion chamber.

Two turbopumps inject hydrogen and oxygen into the combustion chamber. The burnt gases are then ejected at the nozzle outlet. The liquid hydrogen turbopump alone turns at 33 000 revolutions per minute and produces 15 megaWatts of power – more than a high-speed train engine, and there are two turbopumps on Ariane 6 to keep Vulcain 2.1 satisfied with fuel.

Vulcain 2.1 consumes over 327 kg/s of fuel a second and does this for 468 seconds to propel the launcher away from Earth.

A difference with the original Vulcain engine used on Ariane 5 is that the ignition on Ariane 6 is done from the launchpad and not from the rocket itself. Burners underneath the core stage ignite the engine. Having the ignition separate from the rocket allows for weight to be saved and offers more space for the payloads.

The Vulcain 2.1 is developed by ArianeGroup, based in Vernon, France.

Vulcain 2.1 main engine characteristics

- 154 000 kg of liquid oxygen (LOX) and liquid hydrogen (LH2) consumed

- 1371 kN of thrust

- 15 mW turbopump power

- 468 seconds of operation

Access the video

A work of art: Vinci

A third type of Ariane engine, called Vinci, ignites once the upper stage has escaped the clutches of gravity, and places satellites into their precise orbit – it can then ignite again, up to four times in flight. The restarting allows Ariane 6 to reach a larger range of orbits to deliver more payloads on a single launch.

Getting a rocket stage to be restartable is no easy feat and Vinci relies on a second smaller starter engine known as the auxiliary propulsion unit to startup. Without gravity to help pull fuel to the Vinci motor, it relies on the auxiliary propulsion unit to pressurise its liquid oxygen and hydrogen tanks in space.

Once finished its mission, Vinci can fire its engine one last time to deorbit the upper stage and reduce space debris.

The Vinci engine assembly in ArianeGroup Vernon France and complete upper stage is assembled by ArianeGroup in Bremen, Germarny.

Vinci

- 30 000 kg of liquid oxygen (LOX) and liquid hydrogen (LH2) consumed

- 180 Kn of thrust for the Vinci cryogenic engine

- A total of 900 seconds of cumulated operation

Access the video

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland